|

|||

|

|

|||

| ||||||||||

|

|  MIL-S-3443G (AR)

3.10.12 Trigger guard. The trigger guard shall be of metal

construction and shall have sufficient strength to prevent manual

deflection of the bow (causing actuation or blocking of the

firing mechanism) or any permanent deformation of the bow under

the following conditions: The bow of the trigger guard shall

withstand a static load of 220 pounds applied at the outside

surface of the trigger guard bow, perpendicular to the trigger

guard, at the midpoint of the bow and on the vertical center

plane of the shotgun.

3.10.13

Finishes.

3.10.13.1 Machine finish. Machine finishes shall be in

accordance with best commercial practice for the type of shotgun

In the event of a dispute over the comparison of

furnished.

finishes, referee comparison shall be in accordance with ANSI

B46.1.

3.10.13.2 Final protective finish. Unless otherwise

specified (see 6.2), the final finish of the exterior: of metal

parts shall be in accordance with the applicable finishes listed

below. the final protective finishes shall not apply to springs,

or spring pins which may be left bright. However,exterior

exposed surfaces of these parts are subject to the touchup

requirements in accordance with 3.10.14.

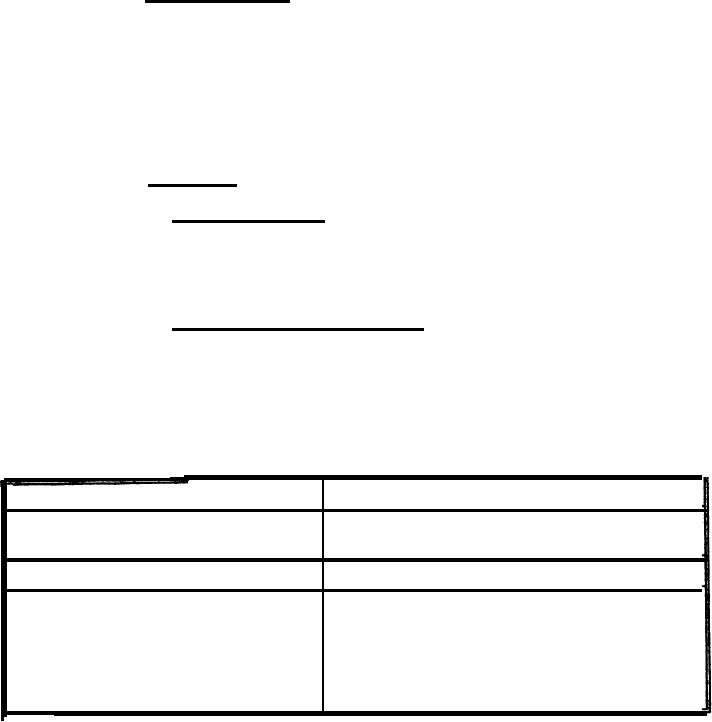

Finish

Material

5.3.1.2 or 5.3.2.2 of MIL-STD-171

Steel (other than corrosion

(see Note 1 and Note 3)

resisting steel)

3.3.2 or 3.3.3 of MIL-STD-171

Corrosion-resisting

steel

7.1.2 or 7.2.2 (dyed black) or

Aluminum and aluminum

7.5* (see Note 2) of MIL-STD-171

alloys

or MIL-A-8625, Type III, Class 1

or 2. Color of finished parts

shall be lusterless uniform dark

grey or black.

Finish number 5.3.2.2 shall not be used on steel

Note 1.

parts that are subjected to rolling or sliding

contact.

Note 2.

Coating thickness for finish number 7.5 shall be

0.0010 + 0.0002 inch.

MIL-C-16173 grade 1 of finish 5.3.2.2 shall not

Note 3.

be used.

14

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |