|

|||

|

Page Title:

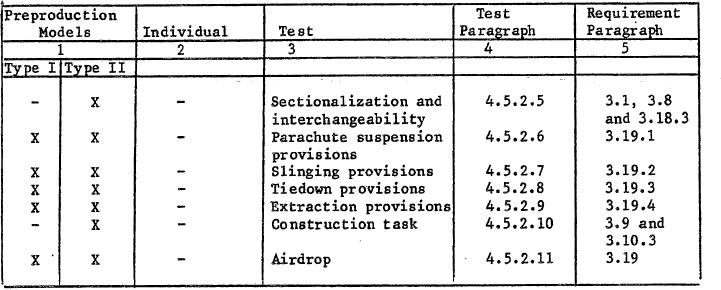

Table I. Examination schedule. - Continued |

|

||

| ||||||||||

|

|  MIL-S-52986(ME)

TABLE II. Demonstration schedule.

Start and operate each scraper as follows:

4.5.2.1 Production run-in.

Operate the scraper in all gears forward and reverse at maximum speeds com-

mensurate with conditions for one-half hour. Stop and restart the engine not

less than five times. Operate all hydraulic controls for five-minute periods.

Hold each hydraulic control in each actuation position until the hydraulic

system reaches relief valve pressure at least five times. Operate the scraper

through not less than 10 full right and 10 full left turns. Make not less than

five abrupt panic stops from a speed not less than 20 mph using the service

brake. Release and reapply the parking brake not less than five times. Turn on

all lights for the duration of the run-in. Evidence of any deficiency, need for

adjustment or maintenance, malfunction of any control, or evidence of leakage of

fuel, lubricants, or hydraulic fluid shall be cause for rejection of the scraper

by the Government until corrected to the Government's satisfaction. The

Government may require additional run-in after deficiencies are corrected. Any

defect found during production run-in shall be prima facie evidence that

scrapers previously accepted are similarly defective unless evidence satisfactory

to the contracting officer, is furnished by the contractor that they are not

similarly defective.

4.5.2.2 Sound level. The contractor shall perform sound level tests in

accordance with SAE J88 and SAE J919. Certified prior test data is acceptable

if available. Nonconformance to the requirements of 3.6.1 shall constitute

failure of this demonstration.

4.5.2.3 Weight. The weight of the scrapers and scraper sections (type II

only) shall be measured with a scale calibrated within 6 months of the

demonstration. Inability to meet the maximum weight limits of 3.7.1 and 3.8

shall constitute failure of this demonstration

15

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |