|

|||

|

Page Title:

Table VI. Classification of defects. |

|

||

| ||||||||||

|

|  MIL-S-62549(AT)

4.4.1.1 Sampling, process average. Sampling may be initiated if the process average for the

first 50 consecutively serial numbered trailers inspected, is less than the Acceptable Quality levels

(AQL) specified in the classification of defects for critical, major, and minor defects. Process

average will be computed as follows:

Number of defects x 100___

Process average = Number of trailers inspected

If the computed process average exceeds the specified AQL, the 100% inspection shall be

performed and continued until such time that the process average for 50 consecutively serial

numbered trailers is less than the specified AQL. When sampling is authorized, MIL-STD-105,

level II will apply.

4.4.2 Samples. Samples shall consist of complete semitrailers with all on-vehicle-equipment

(OVE) installed.

4.4.3 Examinations. Visual, dimensional, and preliminary functional examination shall consist

of examination of trailers for conformance to the applicable drawings and the requirements of this

specification. Examinations shall be preformed utilizing the classification of defects in table VI

with AQLs, as specified.

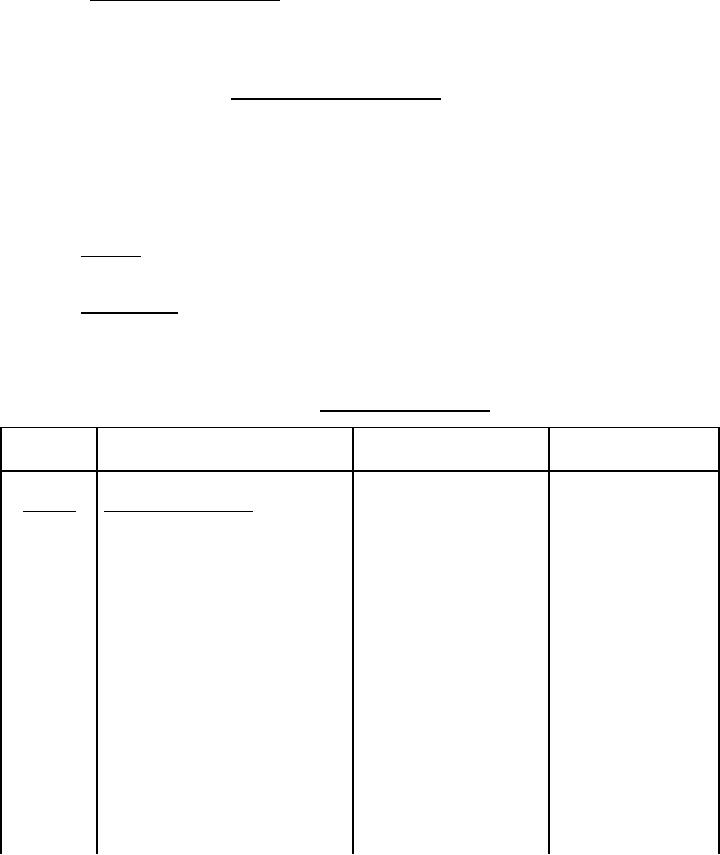

TABLE VI. Classification of defects.

Category

Characteristic

Defect

Method of

Inspection

Critical

AQL 0.0% defective

01

Axles and trunnions

Inoperative

Functional

02

Brake system components

Inoperative

Functional

03

Air line and fittings

Air leaks over

Functional

2 pounds per

square inch per

minute, chaffing

04

Electrical system

Inoperative

Functional

components (turn indicators,

clearance lights, brake

lights including bulbs)

05

Folding gooseneck

Restricted operation,

Functional

will not lock in up

position

06

Intravehicular

Pin misalignment,

Visual

connecting plugs

deformation

25

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |