|

|||

|

|

|||

| ||||||||||

|

|  MIL-S-63383(AR)

4.4.3 Testing. Testing is described in the First Article and

Quality Conformance Inspection Tables and below.

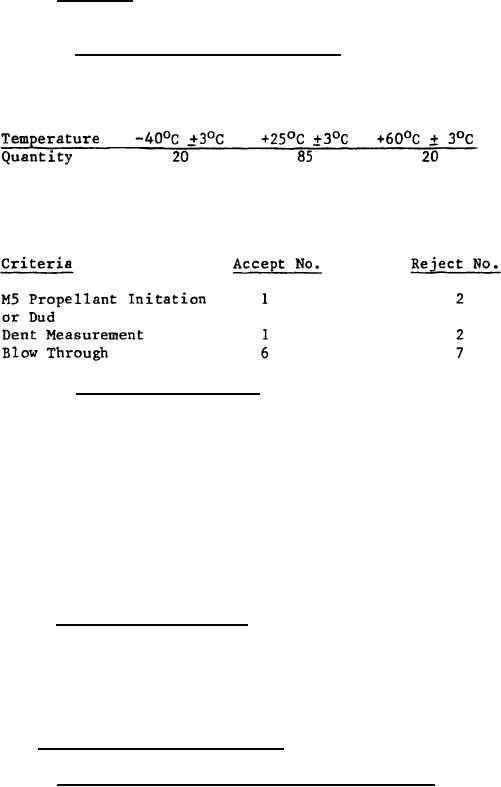

4.4.3.1 Aft ejection charge assembly. One hundred and twenty

five (125) samples shall be randomly selected from each lot and

tested as follows at the specified temperatures.

The lot shall be rejected if the total of rejects from all

temperatures exceeds the following requirements:

4.4.3.2 Stake push off test. A "Push off test" shall be

performed on the front and rear housing closures after being staked

to the housing, to check for integrity of staking. The test shall

be performed on two samples each, prior to the start of each shift,

and then performed on one sample each, after every two hours

production and at the end of the shift, until three consecutive

shifts have been accepted. Thereafter, the test may be performed on

one sample each, prior to the start of each shift, and one sample

each after four hours production and at the end of the shift.

Failure of a test sample at any time will cause the test to revert

to the initial test conditions until three consecutive shifts have

been accepted.

4.4.4 Inspection equipment. The inspection equipment required

to perform the examinations and tests prescribed herein is

identified in the tables beginning with paragraph 4.4.2.1. The

contractor shall submit inspection equipment designs for approval,

in accordance with the terms of the contract. See Section 6 of

MIL-A-48078, and Section 6.3 herein.

4.5 Test methods and procedures

4.5.1 Non-Arming of safe and arming subassembly. The

subassembly shall be tested for the specified non-arming

requirements using the following parts as a minimum for the sample.

16

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |