|

|||

|

|

|||

| ||||||||||

|

|  MIL-S-85419 (AS)

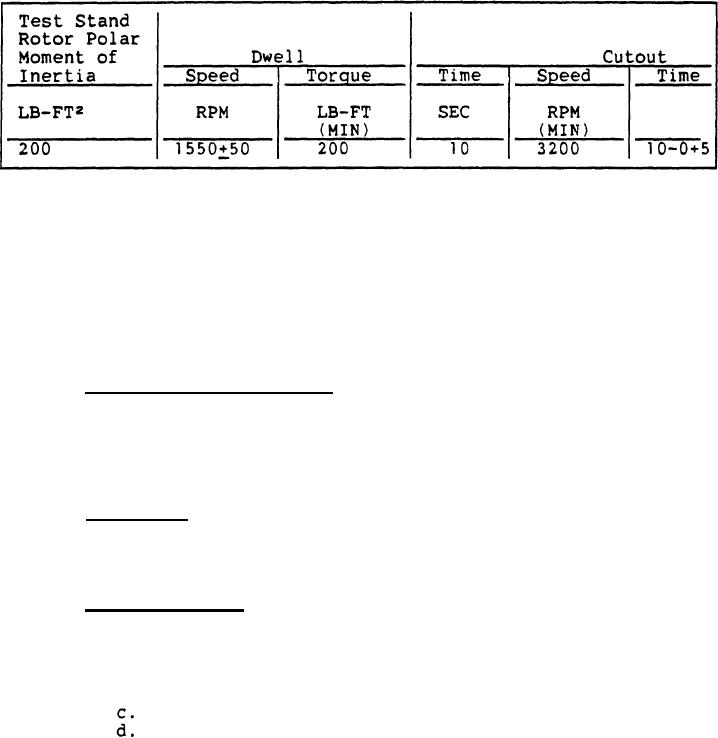

TABLE VI - START CYCLE TEST CONDITIONS

NOTE :

The above values do not allow for flywheel windage losses,

In order to

test stand drag, or inertia of the starter.

determine compliance with this specification, the test

equipment must be calibrated and specific test results

corrected accordingly. If the acceleration specified to

cutout is not developed because of test stand drag

torque, the test stand inertia load may be reduced or

external power may be applied to assist acceleration to

cutout speed.

4.5.2.3 Rapid Starting Cycles. Ten series of rapid starts shall

be run as specified in paragraph 4.5.2.2. Each series shall

consist of three start cycles with no more than 60 seconds

between completion of one cycle and the initiation of the next.

A thirty-minute cooling period will be observed prior to the next

starter operation.

The starter/APU shall be subjected to

4.5.2.4 Cranking.

cranking cycles of 40-second duration with the output shaft speed

limited, by a resistive torque, to 1700 to 1900 rpm as specified

in paragraph 4.5.2.2.

4.5.2.5 APU Operation. The starter/APU shall be operated in one

hour and two hour cycles as specified in paragraph 4.5.2. A one

hour cycle shall consist of

a.

APU start

b.

5 minutes at 1.5KVA

20 minutes at 6KVA

4 minutes at 3KVA

e.

1 minute at no load

f.

4 minutes at 3KVA

20 minutes at 4.5KVA

g.

h.

6 minutes at 1.5KVA

The two hour cycles will double the time at each condition.

33

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |