|

|||

|

|

|||

| ||||||||||

|

|  MIL-S-9968C(IP)

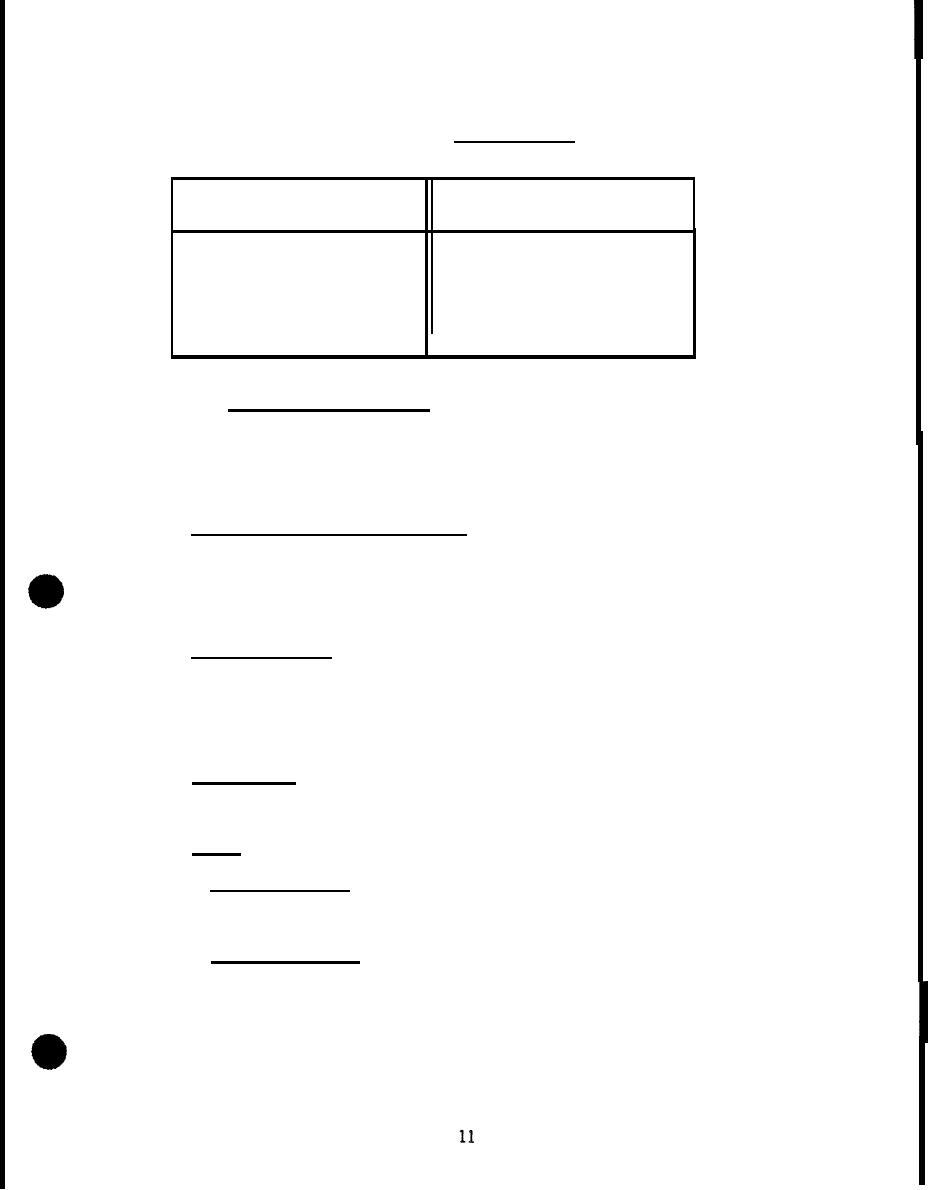

Table IV. Sampling p 1 an

Quantity of

Quantity of

items being

items being

Sample

Sample

purchased

Size

purchased

Size

2

to 8

2

91

to 150

20

"

9

to 15

3

151

to 280

32

16

to 25

5

281

to 500

50

26

to 50

8

501

to 1200

80

51

to 90

13

1201

to 2000

110

4.4.1.1 Dimensional inspection. All sample components shall be inspected

to assure they conform with the dimensional requirements of .3.4.1, 3.4.2, and

3,4.3 as applicable for the type and size required. A measuring device

supplied by the contractor and conforming to the dimensions shown in figure 5

shall be inserted into several groups of four holes along the component

selected at each end to verify hole spacing along and across each component,

4.5 Quality conformance inspection. Quality conformance inspection shall

be applied to each sample component prior to being offered for acceptance

under the contract. Unless otherwise specified (see 6.2), quality conformance

inspection shall consist of the examination in 4.7, the tests in 4.8, and the

inspection in 4.4. The components shall pass the examination, all tests, and

the inspection to be accepted.

4.6 Acceptance test. An acceptance test shall be performed on each

component to ensure conformance with this specification. Unless otherwise

specified (see 6.2), the acceptance test shall be performed in conformance

with paragraph 4.1 herein. The acceptance test shall consist of

the

examination in 4.7, and all tests in 4.8. The components shall pass the

examination and all tests to be accepted.

4.7 Examination. Each component submitted for sampling inspection shall

be visually examined to determine compliance with all requirements of this

specification.

4.8 Tests.

4.8.1 Test conditions. All tests shall be performed in an

indoor

facility with ambient conditions of 410 to 104 Fahrenheit (F) and 20 to

95 percent relative humidity.

4.8.2 Static load test. For the

type I component, a static load test

shall be performed on 5 percent of

the samples selected for testing. The

actual test method and fixtures used

shall be at the option of the supplier

provided that the following conditions

are met:

a.

The test set-up shall be basically as depicted in figure 4.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |