|

|||

|

|

|||

| ||||||||||

|

|  MIL-T-17491H (SA)

3.2 Standard Product. The trucks shall be the standard product of the

supplier except where modifications are necessary to meet the requirements

specified herein. The trucks shall be new and unused except for those units

required to perform the tests specified in paragraph 4.3.2.

3.3 First article (reproduction model). The supplier shall furnished a truck

for examination and test within the time frame specified, to Prove prior to

starting production that -his production methoda and choice of design detail

will produce trucks that comply wit-n the requirements of this specification.

Examination and tests shall be as specified in section 4 and shall be subject

to surveillance and approval by the Government (see 6.3).

3.4 MAterial. MAterial shall be as specified herein. Materials not specified

shall be selected by the supplier and shall be subject to all provisions of

this specification

3.5 Construction.

3.5.1 Chassis and frame. The frame and related structures shall be fabricated

from structural steel, heavy gage sheet steel, steel plate, steel castings or

forgings. The frame and related structure shall provide a rigid unit

structure, and shall afford complete protection for working parts. Overall

length of trucks with handle in vertical position shall not exceed a distance

equal to the fork length plus 22 inches (559 mm) plus or minus 2 inches (51

mm).

3.5.2 Forks. Forks shall be fabricated of formed steel channel cross

sections. Minimum underclearance, with fork lowered, shall be 1 inch (25 mm)

except at load wheel mounting.9 Spacing between forks s-nail be 8-3/4 inches

(222 mm) minimum. Distance between outside edges of the forks shall be 27

inches (686 mm) maximum At all elevations, forks shall be horizontal within a

tolerance of plus 1/16 inch (1.6 mm) and minus 1/8 inch (3 nun) at the ends.

Forks shall `be end tapered on the underside and sides to facilitate entry and

withdrawl from standard military pallets confirming to MIl-P-15011. The lower

fork height shall not exceed 3-1/4 inches (82 mm). The overall dimensions for

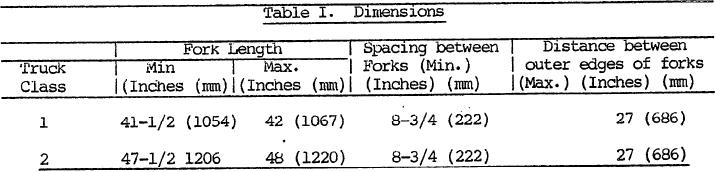

forks shall be as specified in table I.

3.5.3 Raising and lowering mechanism. Tension or compression members

connecting the front and rear linkages shall be made from alloy steel. These

shall be provided with means for adjustment to obtain correct fork height when

in raised and lowered positions. With the truck fully inserted into a military

pallet conforming to MIL-P-15011 perpendicular to the bottom boards of the

pallet, the raising and lowering mechanism shall permit the rear wheels to be

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |