|

|||

|

|

|||

| ||||||||||

|

|  MIL-T-425J

of this specification. Used, rebuilt or remanufactured components, pieces and parts shall not be

incorporated in the pipeline section.

3.4 Performance requirements.

3.4 Hydrostatic pressure. The pipeline section shall withstand the applicable hydrostatic test

pressure specified in table I, without evidence of leakage, sweating, or yielding.

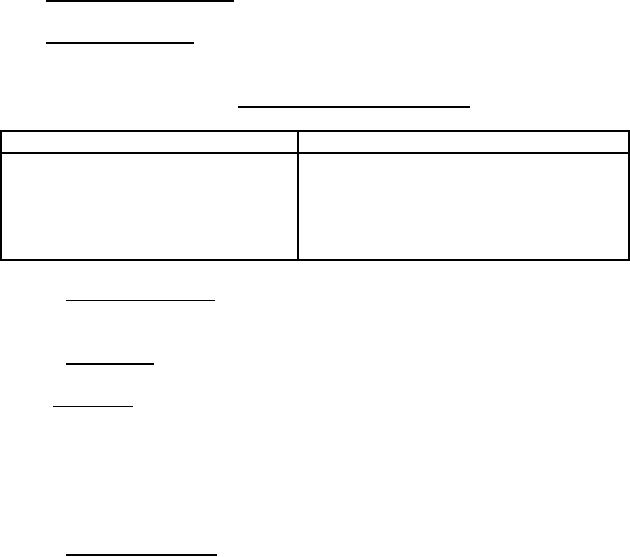

TABLE I. Hydrostatic test pressure ratings.

Nominal tube size (inches)

Minimum test pressure (psi)

2

900

4

900

6

900

8

750

12

600

3.4.2 Tensile requirements. The tensile requirements for the pipeline sections shall be as

specified in API-SPEC 5L, section 4 for grade B steel pipe.

3.4.3 Straightness. Straightness of the pipeline sections shall conform to API-SPEC 5L.

3.5 Fabrication. The thin wall pipes shall be seamless or electric resistance welded steel

pipes. The electric-resistance-welded pipe shall be heat treated after welding to a minimum

temperature of 1000 F or processed in such a manner that no untempered martensite remains.

The nipples shall be fabricated to conform to the tolerances shown in figures 1 in inches. The

nipples shall be inserted into the pipe ends and joined by a circumferential electric weld. The pipe

and the nipples shall have the same outside diameter.

3.5.1 Welders and welding. Before assigning any welder or welding operator to manual

welding work covered by this specification, the contractor shall obtain certification that the

welder or welding operator has passed qualification tests as prescribed by either of the following

listed codes for the type of welding operations to be performed and that such qualification is

effective as defined by the particular code: AWS D1.1 - Structural Welding Code, Steel, ASME

Boiler and Pressure Vessel Code, Section IX, Qualification Standard for Welding procedures,

Welders and Welding Operators.

No welding shall be undertaken until after the welding procedure specifications and welders or

welding operators have been qualified. The contractor is responsible for obtaining certification.

5

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |