|

|||

|

|

|||

| ||||||||||

|

|  MIL-T-46590C

3.4 Hydrostatic pressure. The body shall withstand a hydrostatic pressure of 11,000 pounds per square

inch (psi) for 15 seconds, minimum, without leaking, deformation, or mechanical failure (see 6.4.1).

3.5 Shear pin strength.

3.5.1 Shear pin. The shear pin, after application of protective finish, shall shear when a load of 55 5

pounds is applied at the steady rate of 0.125 inch per minute.

3.5.2 Unlock shear pin. The unlock shear pin, after application of protective finish, shall shear when

a load of 1150 150 pounds is applied at the steady rate of 0.125 inch per minute.

3.6 Welding.

3.6.1 Reservoir assembly. The welding of the reservoir assembly shall comply with the requirements

and shall be welded in accordance with MIL-W-8604 with the exceptions specified herein.

3.6.2 Internal pressure. The reservoir assembly shall withstand a constant internal air pressure of 90

pounds per square inch (psi), minimum, for 15 seconds, minimum, without application of any external load

and shall show no evidence of leakage or mechanical failure (see 6.4.1).

3.6.3 Torque. The weld shall withstand a torque application of 10 inch pounds, minimum, without any

breakage or deformation of any welded joint or component.

3.7 Metal parts assembly. Parts shown in table I shall be combined to produce an assembly which

conforms to the requirements of the metal parts assembly drawing.

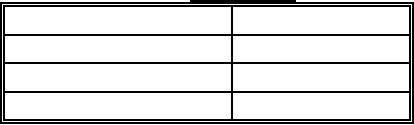

TABLE I. Assembly parts.

Assembled Parts

Method of Inspection

Rod end to piston rod

Hand tight

Firing pin housing to body

Hand tight

All setscrews and cap screws

Wrench tight

3.7.1 Piston rod rotation. Prior to final assembly of the ring nut, the piston rod shall be free to rotate

in a clockwise direction for 360 degrees.

3.7.2 Torque.

3.7.2.1 Hollow lock screw. A torque of 5 inch pounds, maximum, shall be applied to seat the hollow lock

screw on the gasket.

3

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |