|

|||

|

|

|||

| ||||||||||

|

|  MIL-T-48134A (MU)

last control check shall be returned to the contractor for in-

spection for each separate type of defect according to MIL-STD-

105, using an AQL of 0.40 percent for each Major Defect and an

AQL of 0.65 percent for each Minor Defect.

All cavities removed

from production because of some fault may, after reworking, be

returned to production providing they pass the qualification

The contractor may request a change of inspection

test above.

frequency providing he presents objective evidence to the Con-

tracting Officer to substantiate the request.

Contractor design

of gages and test equipment required to perform the inspections

listed herein shall be forwarded to: Commander, Picatinny Arsenal,

Dover, New Jersey 07801

ATTN :

SMUPA-QA-A-M for approval prior

The following sub-paragraphs iden-

to manufacture of equipment.

tify those items and minimum inspections subject to the require-

ments of this paragraph.

4.3.5.1

Cure Time of Plastic Parts. - In establishing a

curing time, dimensionally check ten (10) parts from each cavity

at periodic intervals (e.g., every 30, 60, etc. reins.) until

The curing time will be from

dimensional stability is attained.

the time the part comes out of the mold until dimensional sta-

The inspection data used in determining the

bility is attained.

curing time shall be sent to Picatinny Arsenal, Dover, New Jersey

If any new change in material, cycle

07801

ATTN :

SMUPA-QA-A-N.

time, a reworded cavity or a new cavity is used, a new curing time

shall be established and approved.

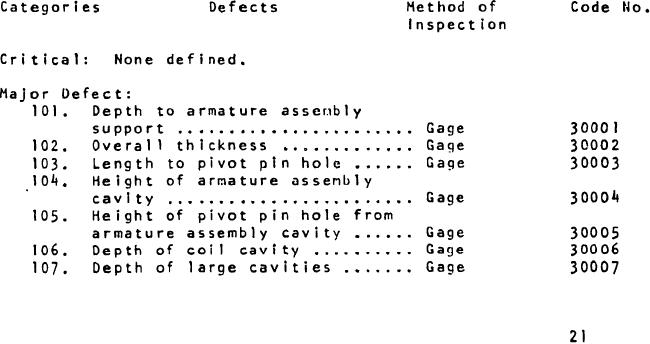

4.3.5.2 Case,

Right Hand (see dwg.

9227701 covering a detail

of dwg. 9227694).

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |