|

|||

|

|

|||

| ||||||||||

|

|  MIL-T-52843C

shall be removable without removal of any other components and shall

not have any projections beyond the side plane of the frame.

3.14 Forks. Structurally, the forklift shall be capable of

supporting a load equal to 300 percent of the rated load on the forks

at the applicable load center with the forks and carrier assembly

centered, and 200 percent of the rated load on the forks at the

applicable load center, with the forks fully shifted to either side

of the forklift without permanent structural deformation or evidence

of mechanical damage. The forks shall be attached to the carrier

assembly in a manner which prevents their lateral movement, except

when the fork position is mechanically changed by the operator. Fork

length, width and thickness shall be as specified below. The taper

shall be on the underside of the forks and no less than 14 inches

long. The fork tine tips shall be chamfered and corners rounded to

facilitate fork engagement.

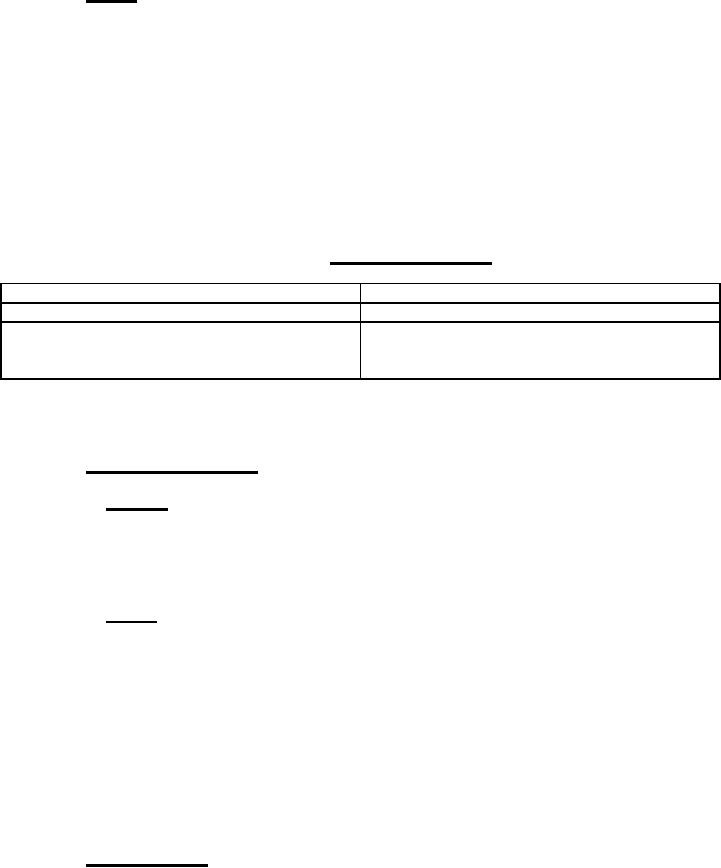

TABLE II. Fork dimensions.

Length

72 in +0-1/2 in

Width

8-1/16 in max

Thickness

2-9/16 in max

tapered to 3/4

in max at tip

NOTE: The heel of the forks may be 3 16 in. thicker/wider in the bend

/

for added strength.

3.15 Wheels and tires.

3.15.1 Wheels. The forklift shall be mounted on four hubs with

four demountable rim and tire assemblies as recommended by SAE J751.

The wheels shall be fastened to the hubs in accordance with the axle

manufacturer's recommendations for off highway application. Wheel

rims shall be in accordance with the TRA yearbook.

3.15.2 Tires. All tires shall be new and unused, wide base, or 65

series, off-the-road type, and of identical size and construction.

The tires shall be pneumatic, low pressure, tubeless, furnished with

type L-2 traction-type tread. Tire loading shall be based on front

axle weight with rated capacity load in the carry position and shall

be in accordance with the TRA yearbook and the tire manufacturer's

published literature for a 5 mph load rating. Valves and caps shall

be in accordance with the TRA yearbook. Large bore valves shall be

furnished. A valve adapter shall be furnished to reduce the large

bore to the standard passenger vehicle size bore. Valve caps shall be

metal with elastomer inner seal. Hydroinflated tires are not

acceptable.

3.16 Wheel guards. Wheelguards shall be furnished at all four

wheels to provide protection for the operator from material being

28

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |