|

|||

|

|

|||

| ||||||||||

|

|  MIL-T-60694B

components (reservoir assembly, body, and firing pin housing) it may be permissible to treat the surfaces with

chemical film Class 1A as specified in MIL-C-5541.

3.4 Residual magnetism. The metal parts assembly shall not deflect the indicator of the compass more

than five degrees in either direction using the procedures of 4.5.5.

3.5 Shear pin strength.

3.5.1 Shear pin. The shear pin, after application of protective finish, shall shear when a load of 55 5

pounds is applied at the steady rate of 0.125 inch per minute.

3.5.2 Unlock shear pin. The unlock shear pin, after application of protective finish, shall shear when

a load of 1150 150 pounds is applied at the steady rate of 0.125 inch per minute.

3.6 Metal parts assembly. Parts shall be combined to produce an assembly which conforms to the

requirements of the metal parts assembly drawing. All threaded joints shall be assembled with sufficient

torque to lightly bottom components, except as noted.

3.6.1 Torque.

3.6.1.1 Hollow lock screw. A torque of 5 1 inch pounds shall be applied to seat hollow lock screw on

the gasket.

3.6.1.2 Ring nut and pellet assembly. Torque requirements shall be as specified in table I. No

movement or deformation shall occur upon application of the breakaway torque.

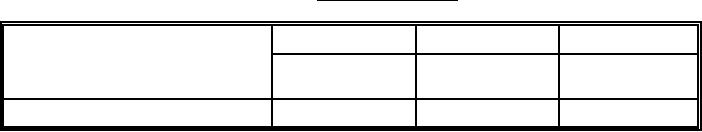

TABLE I. Torque requirements.

A

B

C

Run-On, Min

Seating or Bottoming

Breakaway, Min

Component

(inch pounds)

(inch pounds)

(inch pounds)

Ring nut and pellet assembly with body

40

600 30

400

3.6.2 Piston rod retraction. The piston rod shall not retract into the body upon application of a static

compression load of 25 5 pounds between mounting points.

3.6.3 Fluid leakage. The thruster shall not show evidence of fluid leakage when tested in positions I and

II (see 3.6.3.1 and 3.6.3.2) for a minimum of 12 hours each prior to the installation of the reservoir assembly.

3.6.3.1 Position I. Thruster positioned horizontally with the orifice hole facing down.

3.6.3.2 Position II. Thruster positioned vertically with the piston facing down.

3

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |