|

|||

|

|

|||

| ||||||||||

|

|  MIL-T-62222(AT)

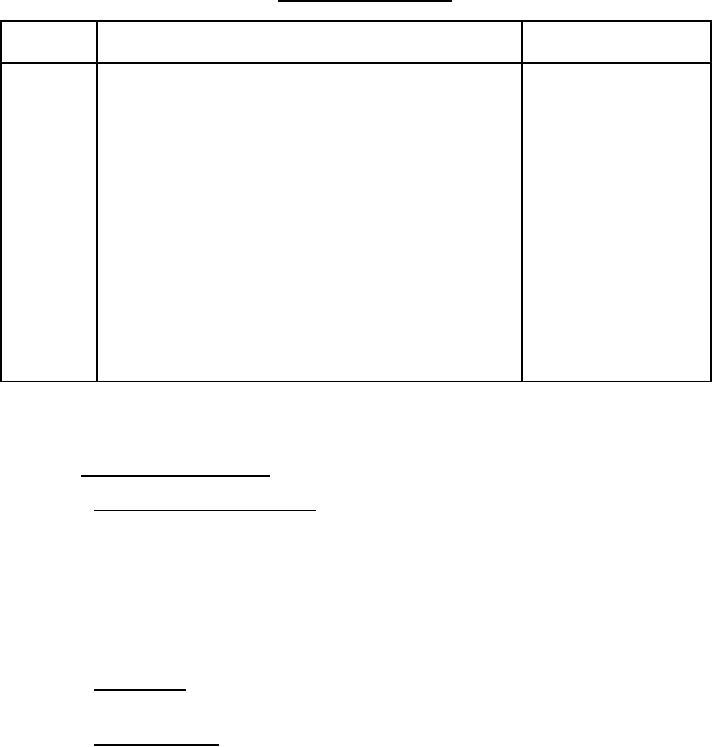

TABLE XIV. Classification of defects - Continued.

Method of

Category

Defect

examination

Visual and functional

217

Turret and gun control improper installation, component

assembly, fluid, or fluid level (see 3.5.3.4).

Visual and functional

Cupola improper installation or assembly (see 3.5.3.5).

218

Visual and functional

Fire control improper installation or assembly

219

(see 3.5.3.6)

Fire extinguisher improper installation or assembly

Visual and functional

220

(see 3.6).

Caution signs improper installation, size or location

Visual

221

(see 3.9.1)

Marking and plates improper, size, location, incomplete

Visual

222

or illegible (see 3.10.2 and 3.10.3).

Workmanship Improper fit, appearance, installation,

Visual and functional

223

adhesion, adjustment, assembly or weldment (see 3.11

and 3.11.1).

1/ Any fuel leakage constitute a special defect and shall result in 100 percent inspection of the

lot for this deficiency.

4.5.3 Quality conformance tests.

4.5.3.1 Acceptance tests (100 percent). After the break-in run (see 3.3.2), each vehicle shall

be examined as specified in 4.5.2, operated a distance of eight miles or more by the contractor,

and subjected to acceptance tests specified in table XIII. Except for equipment and component

installation, and servicing performed by the contractor as a final processing of vehicles for

acceptance, vehicles shall be completely assembled and serviced with fuel, lubricants, and fluids

as specified. Vehicles need not be loaded with rated payload, except for holding test as specified

in 4.7.17.2.5.1. After the tests, the vehicle shall be examined for evidence of fuel or lubricant

leakage, or other defects.

4.5.3.2 Control tests. One of the first 10 vehicles produced, and thereafter one per month,

shall be selected for control testing after a break-in run.

4.5.3.3 Comparison tests. The Government may select vehicles at any time during the

contract production period and subject them to Government proving ground testing. Vehicles

selected shall be examined for the defects listed in table XIV and tested in accordance with

table XIII, including a 2000 mile test for reliability, maintainability, and durability in accordance

with table XV. Vehicles shall be combat loaded with all BII stowed in their allotted space to

conform to 3.4.8. Samples shall not include any vehicles previously tested.

33

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |