|

|||

|

Page Title:

Hydrostatic pressure resistance |

|

||

| ||||||||||

|

|  MILT8504B

3.6 Hydrostatic pressure resistance. When subjected to an internal pressure P or

15,000 pounds per square inch (psi), whichever is less, tubing shall show no bulging,

leakage, or other defects, except that a diametric permanent set to 0.002 inch per inch

of diameter is acceptable. Hydrostatic test pressure shall be calculated according to the

following formula:

S (D2 d2)

P=

(D2 + d2)

Where:

P = test pressure in psi.

S = specified minimum tensile yield strength, psi.

D = maximum permissible outside diameter (nominal OD plus

tolerance), inch

d = maximum permissible inside diameter (computed as D less twice

the minimum permissible wall thickness), inch.

3.7 Dimensions and tolerances

3.7.1 Dimensions. Tubing shall be furnished in the standard diameters and wall

thickness specified in AND10104, as specified by the contract or purchase order. (see

6.2).

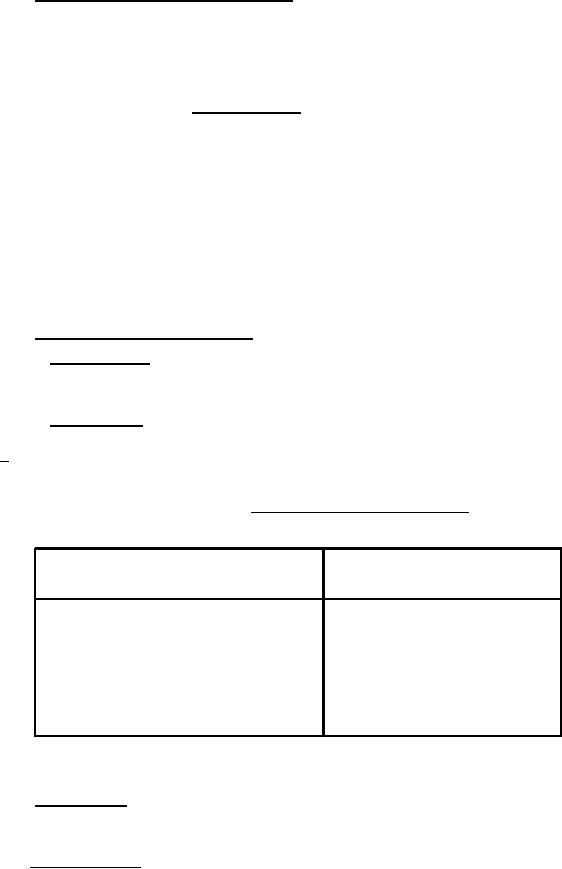

3.7.2 Tolerances. The outside diameter shall not vary from the nominal dimensions by

more than the permissible limits of table IV. Wall thickness variations shall not exceed

+10 percent of the nominal wall thickness.

TABLE IV. Outside diameter tolerance

Size range, outside diameter

Tolerance

(inch)

(inch)

to 0.187 exclusive

+0.003 0.000

0.187 to 0.500 exclusive

+0.004 0.000

0.500 to 1.500 exclusive

+0.005 0.000

1.500 to 2.500 exclusive

+0.010 0.000

2.500 to 3.000 exclusive

+0.010 0.010

Over 3.000 thru 5.000

+0.015 0.015

3.8 Weld bead. When tubing is fabricated by welding, it shall be so processed as to

remove the bead or any dimensional indication of the presence of the weld.

3.9 Straightness. In no portion of any piece of tubing shall the departure from

straightness exceed 0.060 inch in a length of 3 feet.

5

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |