|

|||

|

Page Title:

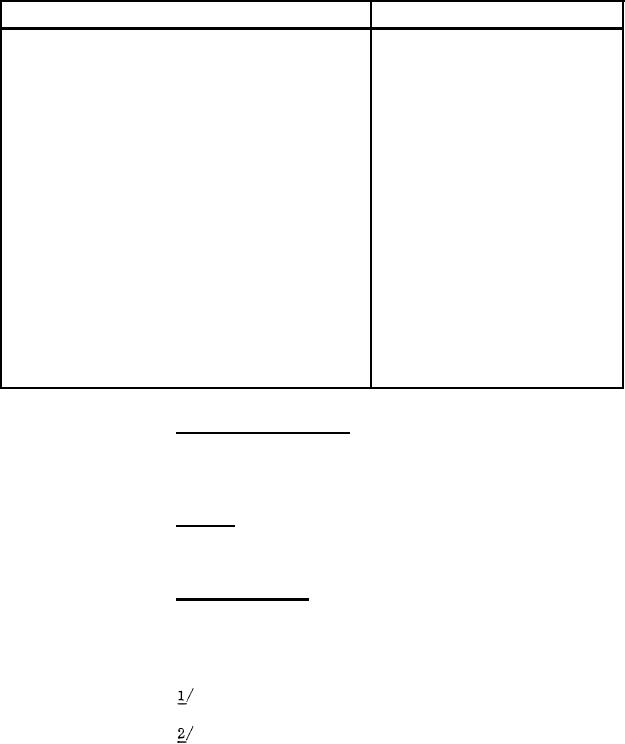

Table III. Classification of Defects for Visual Examination of the Valves |

|

||

| ||||||||||

|

|  MIL-V-18318B

TABLE III

CLASSIFICATION OF DEFECTS FOR VISUAL

EXAMINATION OF THE VALVES

Critical

Minor

1.

Material imperfections-foreign matter

201. Marking-missing, in-

embedded

sufficient, incorrect,

Illegible, or not per-

2.

Surface - unclean, rough, misaligned,

manent.

or containing cracks, nicks, or other

flaws.

202. Color not as specified.

Any component missing, malformed,

3.

fractured, or otherwise damaged.

4.

Any component loose or otherwise

not securely retained,

5.

Incorrect assembling or improper

positioning of components.

Any functioning part that works with

6.

difficulty.

Faulty workmanship or other irregu-

7.

larities.

Preparation for delivery - Each of the fully prepared shipping

4.7.1.2

containers, containing valves selected as a sample unit from the lot shall be examined

to determine that the packaging, packing, and marking conform to this specification.

The classification of defects, Table IV, shall be used to classify the defects found.

Leakage - The outlet of the valve shall be sealed with a suitable

4.7.2

plug. A pressure of 1800 psi shall then be applied to the inlet of the valve and maintained

for a period of 15 minutes. The valve shall pass the requirements specified in 3.7.1.

Pressure and flow - The valve shall be preset with an outlet

4.7.3

pressure of 400 psi and the inlet shall be connected to a 1800 psi pressure source.

The valve shall then be subjected to inlet pressures and flows specified in Table I.

The above test procedure shall be repeated with the valve outlet pressure preset at

70 psi. The valve shall pass the requirements specified in 3.7.2.

For qualification inspection, tests shall be conducted as

specified in 4.6.3.

For quality conformance inspection, valves shall be tested

at an outlet pressure of either 70 psi or 400 psi.

13

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |