|

|||

|

|

|||

| ||||||||||

|

|  MIL-V-190698

c.

The valve handle shall be returned to the neutral position to

permit the buildup of the rated hydraulic pressure-in the

accumulator.

d.

The directional control valve

handle shall be quickly actuated

to permit reverse flow to the

check valve, The valve handle

shall be allowed to remain in

this position for at least three

seconds and then moved to the

original neutral position.

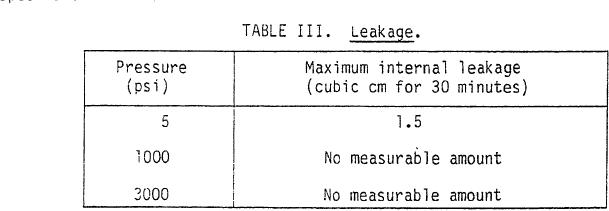

4.5.5 Leakage. This inspection shall be performed with the valve in the

horizontal position. Unless otherwise specified, this inspection shall be

0

conducted at a fluid temperature of 100 F. The valve shall be tested for

internal leakage by applying the pressure listed in table III for a minimum

period of 32 minutes each. The pressures shall be applied in the direction of

reverse flow and the valve poppet shall be mechanically unseated between

pressure applications. The leakage measurement period shall be a least 30

minutes in duration and shall begin two minutes after application of the

required pressure. The internal leakage shall not exceed the amounts stated

in table III. There shall be no measurable external leakage during this

inspection.

4.5.6 Operational inspection. Operational inspection shall consist of

two separate inspections: (1) checking time and (2) checking pressure. These

inspections shall be conducted within a temperature range of 70 to 120F.

When included as part of another inspection, the temperature specified for

that inspection shall apply.

4.5.6.1 Checking time. The valve poppet shall be mechanically actuated

to the full-open position against a static fluid head of 5 psi maximum; it

should then be allowed to check before the static head of fluid decreases to 1

psi minimum, The time between the release of the poppet and the cessation of

fluid flow shall be the checking time and shall not exceed 1.5 seconds.

4.5.6.2 Cracking pressure. Gradually increasing pressure shall be

applied in the free-flow direction beginning with zero pressure. Cracking

pressure is defined as that pressure at which fluid is bypassed through the

valve, and shall be not less than 2 psi or greater than 8 psi.

4.5.7 Pressure drop. This inspection shall be performed at a fluid

0

temperature of 100 F. The pressure drop through the check valve shall be

measured at a flow equal to the rated flow capacity. The fluid flow shall be

7

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |