|

|||

|

|

|||

| ||||||||||

|

|  MIL-V-24642(SH)

REQUIREMENTS

3.

3.1 First article. When specified (see 6.2.1), a sample shall be

subjected to first article inspection (see 4.3 and 6.3).

3.2 General description. This valve is intended for installation in

any position at the inlet of a steam driven turbine for the purpose of tripping

closed to stop steam flow and turbine operation upon electrical command from a

remote sensing system. The valve shall have a single seated disc which is

driven toward the seated position by spring force. A latch device which

opposes the spring force shall be engaged at all times regardless of the

handwheel or disc position until the 12 volt direct current (Vd.c.) solenoid is

energized. Energization of the solenoid will disengage the latch mechanism

allowing the valve to close under spring force. No damage shall occur to the

latch mechanism or seat if the maximum tangential force exerted on the rim of

the handwheel (see 3.4.10.3) is exceeded. A manual tripping device shall be

provided which will allow the valve, regardless of the position of the disc, to

be tripped manually in the event of a loss of electrical power. A handwheel

driven mechanism shall be incorporated to reset the valve after it has tripped

closed. Clockwise rotation of the handwheel to the stop position shall allow

manual engagement of the latch mechanism. Counterclockwise rotation shall then

lift the valve disc to the fully open position. The valve shall incorporate a

gland exhaust connection to prevent excess steam leakage past the stem without

resorting to packing.

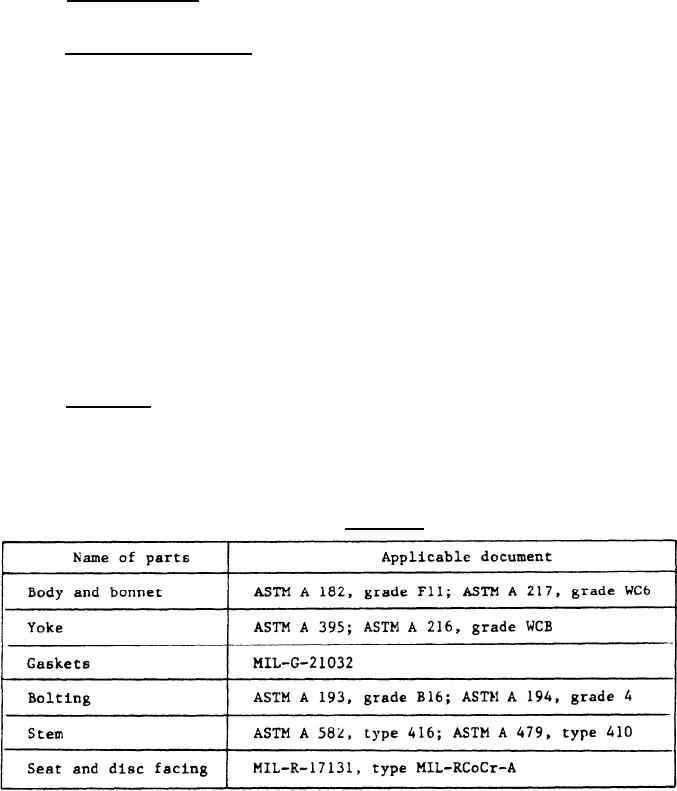

3.3 Material. Valve body and bonnet material composition shall be 1-1/4

percent chromium and 1/2 percent molybdenum. Other material shall be as speci-

fied in table I. Material for parts not listed in table I shall be suitable

for the Intended pressures and temperatures, and selected to prevent galling,

seizing, or excessive wear on operating parts. Clearances shall prevent

interferences due to thermal expansion.

TABLE I.

Material.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |