|

|||

|

|

|||

| ||||||||||

|

|  MIL-V-24642(SH)

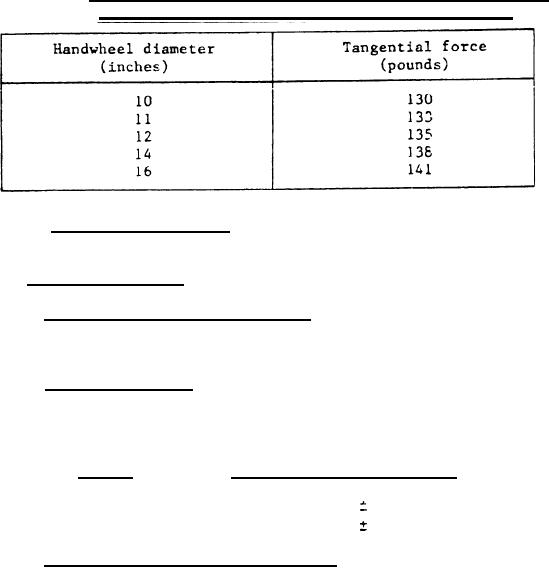

TABLE II.

Maximum allowable tangential force to operate valve

reset mechanism based on valve handwheel size. - Continued

Handwheels shall be secured to the valve

3.4. 10.4 Handwheel fastening.

stem with a locknut.

3.4.11 Body subassembly.

3.4.11.1 Pressure-temperature ratings. The design and pressure-

temperature rating for valves shall be 600 and 1,500 class in accordance with

ANSI B16.34.

3.4.11.2 End connections. The valves shall be furnished with 2-inch

nominal pipe size (rips) flanged ends in accordance with ANSI B16.5. Valves

shall be of a basic globe configuration with inline inlet and outlet ports.

Flange to flange distance shall be as shown below:

Rating

Flange to flange distance

13-3/4 inches

1/32 inch

600 class

1,500 class

16-1/2 inches

1/32 inch

3.4.11.3 Bonnet and bottom flange joints. Bonnet and bottom flange

(where applicable) shall be flanged for attachment to the body and shall be

located by body guiding (i.e., a close tolerance fit between machined diameters

on the body, bonnet and bottom flange) rather than depending on studs or bolts

for location. Spiral wound gaskets shall be fully retained, and the joints

shall have metal-to-metal take-up to provide controlled compression of the

gaskets. Joint design shall assure parallel alinement of the valve guiding

surfaces. Sufficient bolting area shall be provided to retain metal-to-metal

make-up. Flanges shall be secured by one of the following:

(a) Stud bolts threaded the entire length and fitted with a nut on

each end. Threads on bolts and nuts shall be a class 2 fit.

(b) Tap-end studs with interference fit at the tap end and a class 2

fit at the nut end. Interference fit shall be in accordance

with ANSI B1.12.

(c) Hex head cap screws in accordance with ANSI B18.2.1 or hexagon

socket head cap screws in accordance with ANSI B18.3.

7

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |