|

|||

|

Page Title:

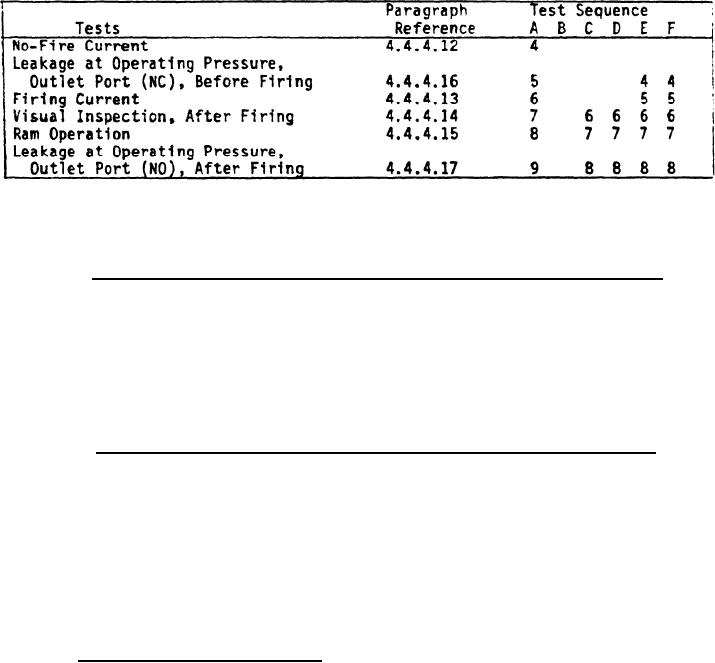

Leakage at operating pressure, outlet port (NO),after firing |

|

||

| ||||||||||

|

|  MIL-V-82443(OS)

AMENDMENT 1

Page 15

4.4.4.16, delete and substitute:

"4.4.4.16, Leakage at operating pressure, outlet port (NC), before firing.

With the squib in the valve body and before firing, the valve shall be

subjected to a pressure of 4500 200 psig using dry inert gas. Pressure

shall be applied to the outlet port (NC) for a period of 5 minutes with the

valve submerged in water. There shall be no evidence of leakage. The

pressure shall be released and the valve inspected for evidence of permanent

distortion."

4.4.4.17, delete and substitute:

"4.4.4.17, Leakage at operating pressure, outlet port (NO),after firing.

With the squib remaining in the valve body after firing, the valve shall be

subjected to a pressure-of 4500 200 psig using dry inert gas. Pressure

shall be applied to the outlet port (NO) for a period of 5 minutes with the

valve submerged in water. There shall be no evidence of leakage. The

pressure shall be released and the valve inspected for evidence of permanent

distortion."

Page 17

4.5.6.1, delete and substitute:

"4.5.6.1 Leakage at proof pressure. Prior to assembly of a squib into the

valve body, the valve body shall be subjected to a pressure of 4500 + 200 psig

using dry inert gas. Pressure shall be applied to the outlet port (NC) for 5

minutes. The valve shall be submerged in water and shall show no evidence of

leakage. The pressure shall be released and the valve inspected for evidence

of permanent distortion. This test shall be repeated with pressure applied

for 5 minutes simultaneously to the Inlet and outlet (NO) ports. The valve

shall be re-examined for evidence of permanent distortion."

3

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |