|

|||

|

Page Title:

Table II. Dimensional tolerances. |

|

||

| ||||||||||

|

|  MIL-E-23765B(SH)

3.5 General requirements.

3.5.1 Finish. Electrodes and rods shall have smoothly finished surfaces,

free from slivers, depressions, scratches (excluding seams for alloyed cored

electrodes), and scale or foreign matter that would adversely affect the welding

characteristics, operation of the equipment, or properties of the deposited metal.

3.5.2 Chemical composition. The chemical composition of bare electrodes

(wire form) and rods or weld metal deposited by alloyed cored electrodes shall

be as specified in the detail specification.

3.5.3 Mechanical properties. The deposited weld metal shall exhibit

mechanical properties specified in the detail specification.

3.5.4 Soundness. Radiographs of groove welds shall show that the welds

conform to class 1 production weld requirements in accordance with NAVSEA

0900-LP-003-9000.

3.5.5

Alloy identity. Each end of rod, strip

or wire to be spliced during

processing

shall be sampled for alloy identity (see

4.7.5), except when splicing

is done to

repair a wire break without removing the

wire from the process line.

The sample

shall be tested for alloy identity prior

to shipment of the lot.

3.5.5.1 Both ends of each coil, drawn to finish size, shall be tested for

alloy identity (see 4.7.5) before rewinding, spooling, or straightening and

cutting into rods or electrodes.

3.5.5.2 When specified (see 6.2.1), each electrode or rod shall be tested

for alloy identity in accordance with 4.7.5 after final marking. Identification

of each spool, coil or container of electrodes tested after final marking and

meeting the acceptance criteria of 4.7.5 shall include the words "Alloy tested".

3.6 Spooled and coiled electrodes.

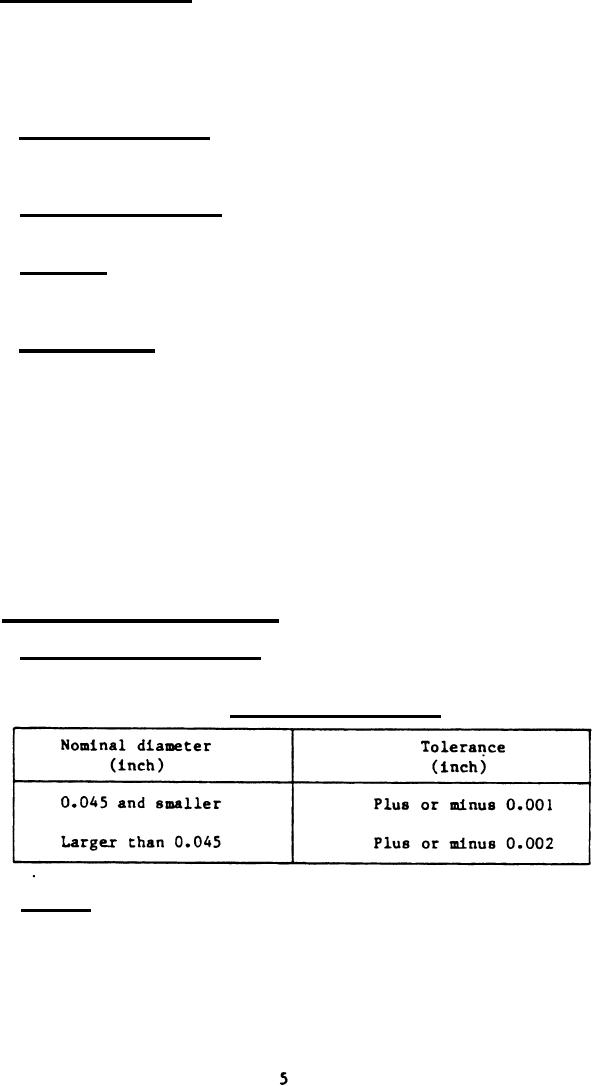

3.6.1 Tolerance (diameter size). Diameter of electrode shall not vary

from the nominal diameter by more than the llmits specified In table II.

TABLE II.

Dimensional tolerances.

3.6.2 Winding. Each spool, coil and drum shall be wound of one continuous

length of electrode made from a single lot of metal, as specified in the detail

specification. The winding shall avoid producing kinks, waves, or sharp bends

and shall be free to unwind without restriction. The starting end of spooled and

coiled electrode shall be firmly fastened so that it is readily visible to the

welder or welding operator and both ends of the electrode shall be accessible for

inspection purposes.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |