|

|||

|

|

|||

| ||||||||||

|

|  -

MIL-P-14462A

The Government reserves the right to Per-.

104. Graduation marks not filled as spec-

form any of the inspections set forth in the

ified. Black medium chipped or

specification where such instructions are

peeling.

deemed necessary to aSsure supplies and

105. Identification marking not as spec-

services conform to prescribed requirements.

ified.

4.2 Classification of inspection Inspection

4.3.2 Tests. The protractor shall be tested

shall be classified as follows:

as specified in table I. Failure to PasS any test

shall be cause for rejection.

(a) Preproduction inspection of the pro-

tractors.

4.4 Production inspection.

(b) Production inspection of the pro-

4.4.1 Sampling. Sampling for examination

tractors.

and tests shall be in accordance with Standard

(c) Inspection of preparation for deliv-

MIL-STD-105. Inspection level shall be L-II

ery.

for examination and L-1 for tests.

4.3 Preproduction inspection.

4.4.2 Examination. Samples selected in ac-

4.3.1 Examination. The protractor shall be

cordance with 4.4.1 shall be examined for the

examined for the following defects. Presence

defects listed in 4.3.1. AQL shall be 2.5 per-

of one or more defects shall be cause for re-

cent defective.

jection.

4.4.3 Tests.. Samples selected in accordance

101. Dimensional nonconformance to the

with 4.4.1 shall be tested as specified in table

drawings.

I. AQL shall be 0.10 percent defective. Any

102. Nicks, burrs, or rough edges on ruling

sample failing to pass one or more tests shall

and protractor edge or face.

be considered defective.

103. Graduation marks not sharply de-

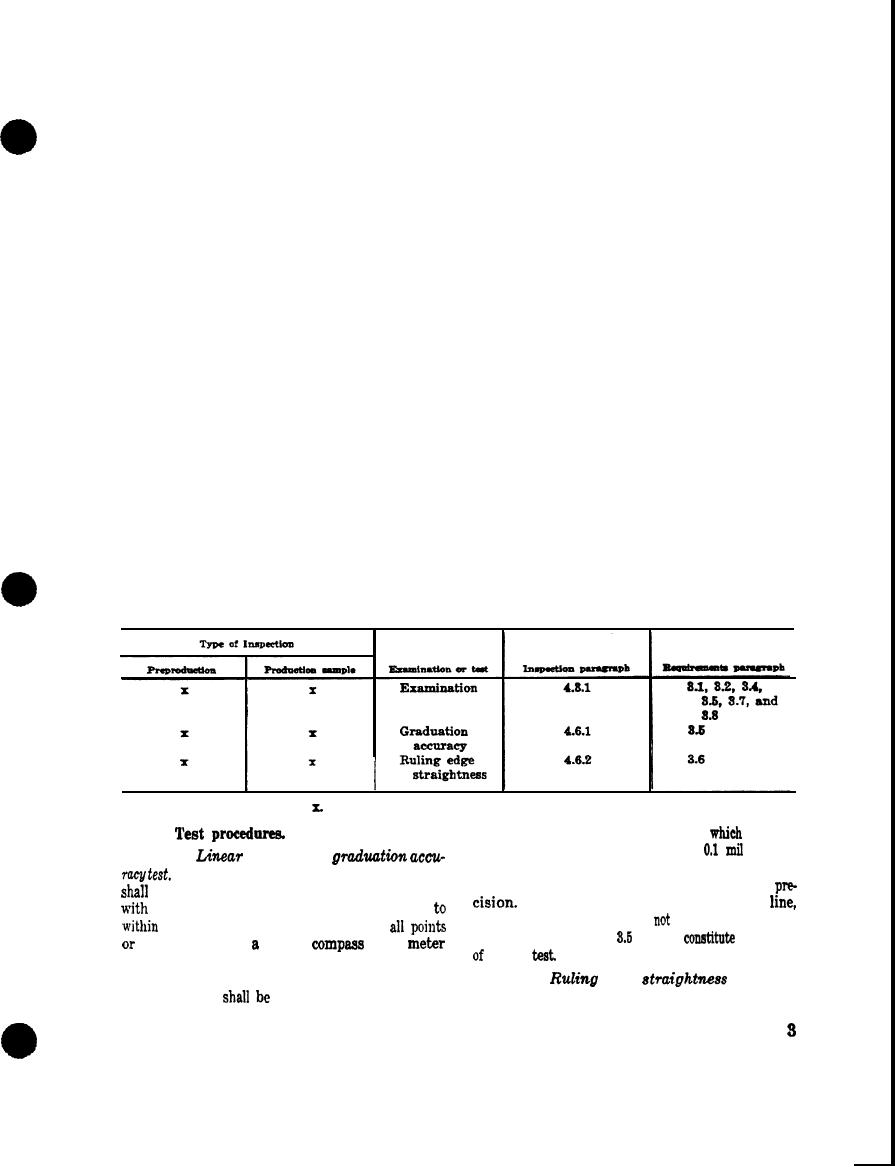

4.5 Inspection schedule Inspection sched-

fined, missing, or not of proper

ule is contained in table I.

width.

Perform inspection marked

q

comparison with a master scale

is ac-

4.6

curate to within plus or minus

or by

4.6.1

and angular

means of a circular measuring machine, sine

The accuracy of linear graduations

bars, or angular gage blocks of similar

be determined by direct comparison

Evidence of any graduation

a master scale which is accurate

either linear or angular,

within the toler-

plus or minus 0.001 inch at

shall

failure

ances specified in

by means of beam

and

this

bar having a least reading of not more than

edge

4.6.2

test. The

0.025 millimeter. The accuracy of angular

straightness of the ruling edge of the range

graduations

determined by direct

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |