|

|||

|

|

|||

| ||||||||||

|

|  MIL-R-19365D

4.5 Retention of qualification. Every 24 months, the manufacturer shall veri fy the retention of

qualification to the qualifying activity. In addition, the manufacturer shall immediately notify the qualifying

activity whenever the group B inspection results indicate failure of the qualified product to meet the

requirements of this specification. Verification shall be based on meeting the following requirements:

a. The manufacturer has not modified the design of the item.

b. The specification requirements for the item have not been amended so far as to affect the

character of the item.

c. Lot rejection for group A inspection does not exceed the group A sampling plan.

d. The requirements for group A inspection are met.

When group B requirements were not met and the manufacturer has taken corrective action satisfactory

to the Government, group B inspection retesting shall be instituted.

4.6 Conformance inspection.

4.6.1 Inspection of product for delivery . Inspection of product for delivery shall consist of group A and

B inspection.

4.6.1.1 Inspection lot . An inspection lot, as far as practical, shall include resistors of any style within a

given group shown in table IV without regard to resistance value or resistance tolerance, produced under

essentially uniform conditions and offered for inspection at one time. Resistors that differ in design,

construction, materials, and terminal type shall not be included in one lot.

4.6.2 Group A inspection. Group A inspection shall consist of the examinations and test specified in

table IV, and shall be made on the same set of sample units, in the order shown.

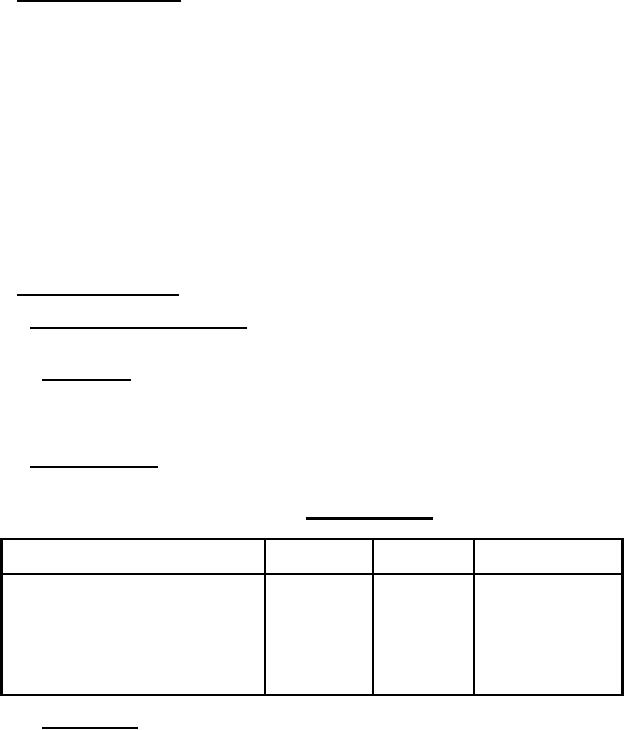

TABLE IV. Group A inspection.

Test

Requirement

Method

Number of samples

paragraph

Paragraph

DC resistance

3.7

4.7.1

Visual and mechanical examination

4.7.2

Overall body dimensions

3.4

See 4.6.2.1

Other physical dimensions

3.4

Terminals

3.4.3, 3.4.3.1

Marking

3.19

Workmanship

3.22

4.6.2.1 Sampling plan. A sample of parts from each inspection lot shall be randomly selected in

accordance with table V, if one or more defects are found, the lot shall be rescreened and defects

removed. After screening and removal of defects, a new sample of parts shall be randomly selected in

accordance with table V, if one or more defects are found in the second sample, the lot shall be rejected

and shall not be supplied to this specification. Resistance values shall be representative, and where

possible, in proportion to the resistors in the inspection lot.

17

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |