|

|||

|

Page Title:

Table I. Chemical composition (product analysis) 1/ 5/. |

|

||

| ||||||||||

|

|  MIL-A-46100D (MR)

w/INT. AMENDMENT 2

PLATE THICKNESS (T)

INSIDE RADIUS

1/8 to 5/16

4T

Over 5/16 to 1/2

6T

Over 1/2 to 3/4

8T

Over 3/4 to 1

10T

Over 1 to 2

12T

NOTE: The bend test on material thicker than 1/2 inch shall be negotiated between the steel

supplier and contractor if bending is required. Dimensions for thickness over 1/2 inch are

listed for information purposes only.

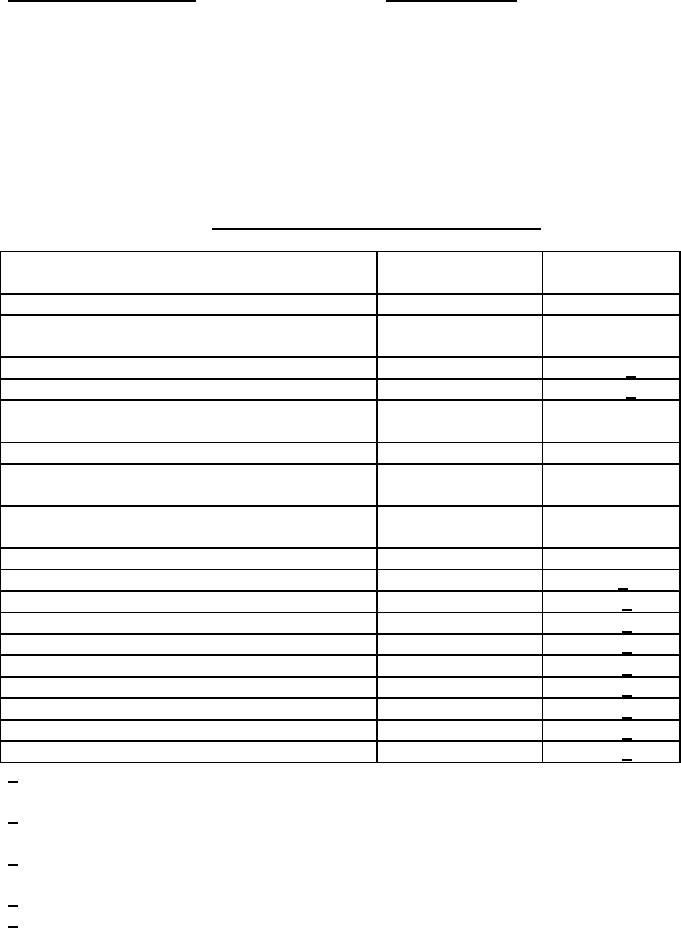

TABLE I. Chemical composition (product analysis) 1/ 5/.

Maximum Range,

Maximum

Element

Percent

Limit, Percent

Carbon

0.10

0.32

Manganese: Up to 1.00% incl

0.30

-

Over 1.00%

0.40

-

Phosphorus

-

0.020 2/

Sulfur

-

0.010 2/

Silicon: Up to 0.60% incl

0.20

-

Over 0.60% to 1.00% incl

0.30

-

Nickel

0.50

-

Chromium: Up to 1.25% incl

0.30

-

Over 1.25%

0.40

-

Molybdenum: Up to 0.20% incl

0.07

-

Over 0.20%

0.15

-

Vanadium

0.15

-

Boron

-

- 3/

Copper

-

0.25 4/

Titanium

-

0.10 4/

Zirconium

-

0.10 4/

Aluminum

-

0.10 4/

Lead

-

0.01 4/

Tin

-

0.02 4/

Antimony

-

0.02 4/

Arsenic

-

0.02 4/

1/ This table lists the maximum range for elements of the manufacturer's established

chemical composition.

2/ Phosphorus and sulfur shall be controlled to the lowest attainable levels but in no case

shall the combined phosphorus and sulfur content exceed 0.025 percent.

3/ When the amount of boron is specified in the alloy, its content so determined by heat

analysis shall not exceed 0.003%.

4/ When the amount of an element is less than 0.02% the analysis shall be reported as 0.02%.

5/ Elements not listed in table, but intentionally added, shall be reported.

5

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |