|

|||

|

Page Title:

Table II. Minimum charpy V-notch impact resistance requirements at -40F 2F. |

|

||

| ||||||||||

|

|  MIL-A-46100D (MR)

w/INT. AMENDMENT 2

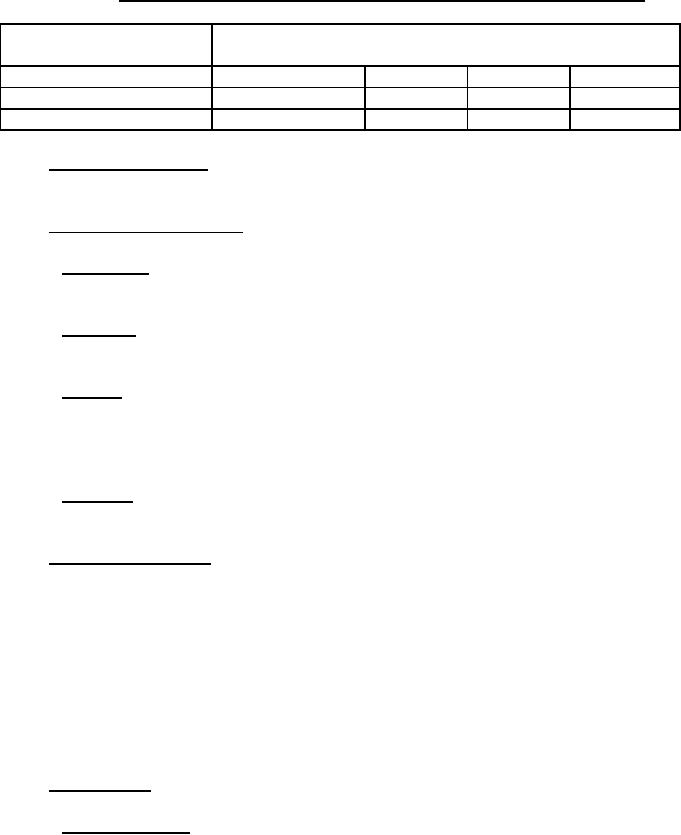

TABLE II. Minimum charpy V-notch impact resistance requirements at -40F 2F.

Impact resistance for standard depth specimens

Specimen orientation

(Average of 2 or more specimens), ft. lbs.

Standard width

3/4 width

1/2 width

1/4 width

Transverse (T-L)

10.0

7.5

5.0

2.5

Longitudinal (L-T)

12.0

9.0

6.0

3.0

3.2.6 Ballistic requirements. Ballistic requirements shall be in accordance with the

appendix of this specification.

3.2.7 Dimensions and tolerances.

3.2.7.1 Dimensions. Plates shall comply with the dimensions specified in the applicable

drawings or in the contract or order (see 6.2).

3.2.7.2 Thickness. The thickness tolerance of each plate, after final treatment, shall be in

accordance with table III for the thickness specified.

3.2.7.3 Flatness. Unless otherwise specified in the contract or order, the flatness tolerance

of each plate shall be within the requirements specified in table IV. Tighter tolerance

requirements shall be specified in the contract or order and shall be as agreed upon between

the contractor and the procuring activity.

3.2.7.4 Waviness. Unless otherwise specified in the contract or order, the waviness

tolerance of each plate shall be within the requirements of table V.

3.2.8 Identification marking. Identification marking shall be legibly painted and records

shall be such as to ensure positive identification of all plates, including test samples and

specimens, with the lot and corresponding heat from which they were produced. Marking

shall be approximately six inches in from the edge of the plate. The key to identification

symbols shall be furnished to the inspector prior to submittal for inspection. First article

and acceptance ballistic test plates shall also be marked with the manufacturer's name or

trademark, the number of this specification, and the ordered plate thickness in inches. First

article plates shall be marked "PRE," acceptance plates "ACC," and retest plates shall be

marked "Rl" and "R2." If a second set of retest plates are submitted they shall be marked

"RR1" and "RR2." The primary plate rolling direction shall be identified.

3.2.9 Workmanship.

3.2.9.1 Surface condition. The top and bottom surface of each plate shall be free from the

following surface defects: slivers, laps, checks, seams, blisters, snakes, cold shuts, cracks,

burning, mechanical seams, mechanical gouges and laminations (see 6.10). The surface of

each plate shall be such that mill scale or oxidation product shall not interfere with

determination of acceptability. Imperfections listed above, which are of such a nature as to

affect the fabrication of the materials, shall be rejected.

6

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |