|

|||

|

|

|||

| ||||||||||

|

|  MIL-C-11272D

w/Amendment 1

4.4.4 Verification of qualification. Every 6 months, the manufacturer shall verify the retention of qualification to the

qualifying activity. In addition, the manufacturer shall immediately notify the qualifying activity whenever Group B

inspection results indicate failure of the qualified product to meet the requirements of the specification.

Verification of qualification shall be based on meeting the following requirement

a.

The capacitor has not been modified.

b.

Lot rejection for group A inspection does not exceed the group A sampling plan.

c.

Periodic group B inspection requirements have been met.

4.5 Conformance inspection.

4.5.1 Inspection of product for delivery. Inspection of product for delivery shall consist of group A inspection.

4.5.1.1 Inspection lot. An inspection lot shall consist of all capacitors of the same style produced under

essentially the same conditions, and offered for inspection at one time.

4.5.1.2 Group A inspection. Group A inspection shall consist of the examinations and tests specified in table IV,

in the order shown.

4.5.1.2.1 Sampling plan. The sampling plan shall be as specified in table IV In the event of one or more failures,

the lot shall be rejected.

4.5.1.2.2 Rejected lots. If an inspection lot is rejected, the supplier may rework it to correct the defects, or screen

out the defective units, and resubmit for reinspection. A new sample of parts shall be randomly selected in

accordance with Table IV. Such lots shall be kept separate from new lots, and shall be clearly identified as

reinspected lots. If one or more defects are found in this second sample, the lot shall be rejected and shall not be

supplied to this specification.

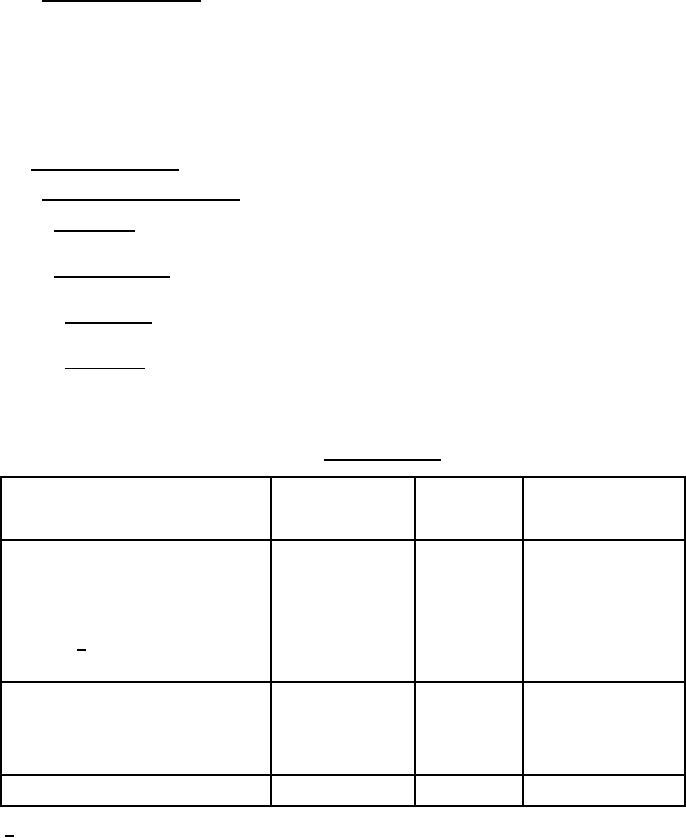

TABLE IV. Group A inspection.

Sampling procedure

Test method

Examination or test

Requirement

paragraph

paragraph

See table V

Visual and mechanical examination:

4.6.1

Material

3.3 to 3.3.2, incl

Physical dimensions

3.4

Design and construction (other than

physical dimensions)

3.4 to 3.4.3, incl

Marking 1/

3.19

Workmanship

3.20 to 3.20.2, incl

Dielectric withstanding voltage

3.5

4.6.2

See table V

Insulation resistance

3.7

4.6.4

Capacitance

3.8

4.6.5.2

Dissipation factor

3.9

4.6.6

Barometric pressure

3.6

4.6.3

Life (performance check)

3.15.1

4.6.12.2.1

See table VI

1/ Marking defects are based on visual examination only. Any subsequent electrical defects shall not be used as

a basis for determining marking defects.

10

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |