|

|||

|

Page Title:

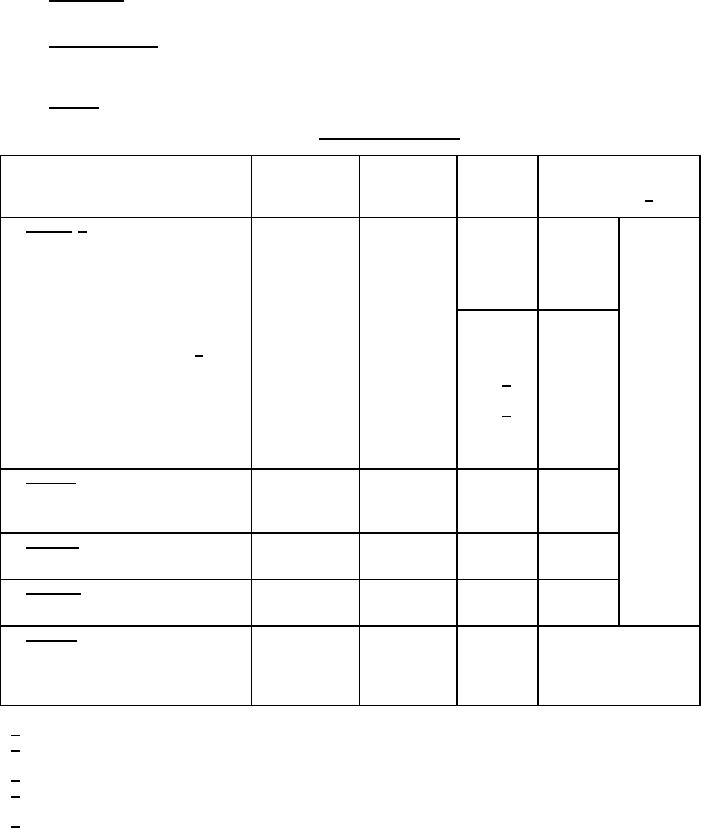

Table III. Qualification Inspection |

|

||

| ||||||||||

|

|  MIL-C-11272D

w/Amendment 1

4.4.1 Sample size. The number of capacitors to be subjected to qualification inspection shall be as specified in

the appendix to this specification.

4.4.2 Inspection routine. The sample shall be subjected to the inspections specified in table III, in the order

shown. All sample units shall be subjected to the inspection of group I. The sample shall then be divided as

specified in table III for groups II to V inclusive.

4.4.3 Failures. Failures in excess of those permitted in table III will be cause for refusal to grant qualification.

TABLE III. Qualification inspection.

Number of

Number of failures

sample

Test method

Examination or test

Requirement

permitted 1/

units to be

paragraph

paragraph

inspected

Group I 2/

Visual and mechanical examination

4.6.1

Material, design, construction and

0

2

3.1, 3.3, 3.4.3,

incl, and 3.20

to 3.20.2, incl

Visual and mechanical examination

4.6.1

Physical dimensions, marking 3/ and

3.4 and 3.19 to

3.20.2, incl

61 4/

Dielectric withstanding voltage

3.5

4.6.2

1

or

Barometric pressure

3.6

4.6.3

62 5/

Insulation resistance

3.7

4.6.4

Capacitance

3.8

4.6.5.1

Dissipation factor (DF)

3.9

4.6.6

Quality factor (Q)

3.10

4.6.7

2

Group II

Shock (specified pulse)

3.11

4.6.8

1

12

Vibration, high frequency

3.12

4.6.9

Thermal shock and immersion

3.13

4.6.10

Group III

Moisture resistance

3.14

4.6.11

1

12

Group IV

Life

3.15

4.6.12

1

24

Group V

Solderability

3.16

4.6.13

Terminal strength

3.17

4.6.14

1

12

Temperature coefficient and

3.18

4.6.15

capacitance drift

1/ A sample unit having one or more defects shall be considered as a single failure.

2/ With the exception of the internal visual and mechanical examination, all tests of this group are nondestructive

tests.

3/ Marking will be considered a failure only if it becomes illegible as a result of any of the tests.

4/ For single-type submission, 1 additional sample unit is included in each sample of 63 sample units to permit

substitution for failure permitted.

5/ For combined-type submission, 2 additional sample units (1 of the highest and 1 of the lowest capacitance

value) are included in each sample of 64 sample units to permit substitution for the permitted failure (either the

highest or lowest capacitance value).

9

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |