|

|||

|

Page Title:

Table III. Scheduled maintenance requirements. |

|

||

| ||||||||||

|

|  MIL-C-18087A(SH)

3.3.2.2 Interchangeabili ty. In no case shall parts be physically inter-

changeable or reversible unless such parts are also interchangeable or reversible

with regard to function, performance and strength.

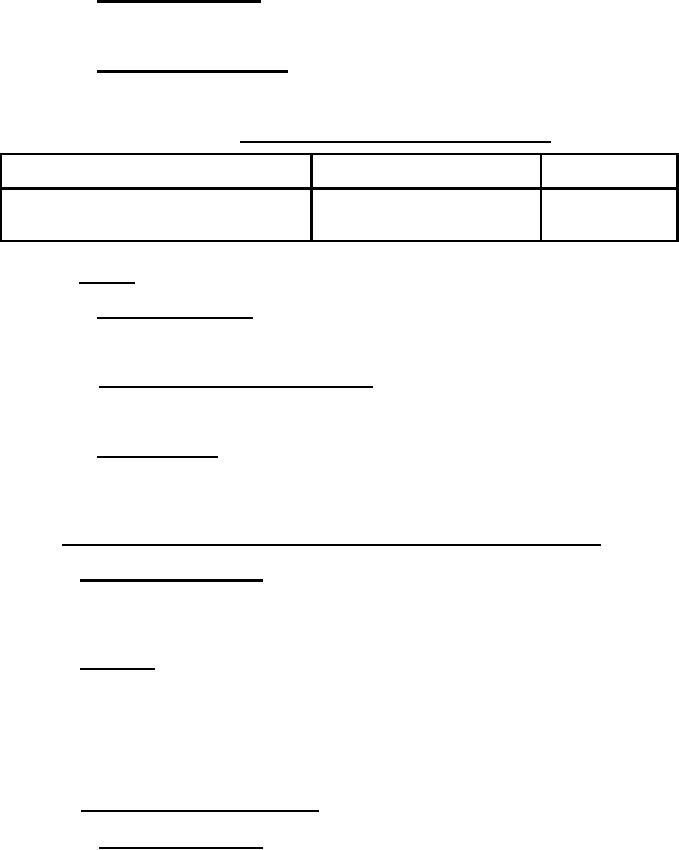

3.3.2.3 Scheduled maintenance. Table III provides the minimum requirements

for scheduled (periodic) maintenance. Equipment vendors shall submit other

necessary periodic maintenance requirements for their equipment,

Schedul ed maintenance requirements.

TABLE III.

Clutch type

Maintenance interval

Action

Semi-annual

Inspect

All types

Quarterly

Self-contained lubricant type

Lubricate

3.3 3 Safety.

3.3.3.1 safety objectives. Clutches shall be designed and constructed to

minimize or preclude hazard to equipment or personnel during testing and when

installed and operational on board ship as specified (see 6.2).

3.3.3.2 Equipment and personnel safety. Appropriate safety provisions

shall be included in design, test, and ship installation to satisfy equipment

and personnel safety requirements specified in MIL-STD-882 (see 6.3).

Where clutch operating requirements u ay be hazardous

3.3 3.3 Safety hazard

to equipment or personnel, special instructions and safety requirements shall

be imposed by the contractor to the depth required by means of design, warning

plates, and training requirements.

3.4 Construction, general requirements (see 6.3 and app endix B).

3.4 1 Revolution indicator. For all clutch types, except type I and VI,

class A, a revolution indicator, located as approved by the contracting activity,

shall be provided to indicate the revolutions of the driving or driven

shafts to facilitate engagement of clutches at near synchronous speed.

3.4.2 Controls. Controls provided for the pneumatic or hydraulic systems

of all clutches shall be suitable for remote operation (see 6.2). Location and

safety features of controls shall be as approved by the contracting activity.

Provision shall be made for gauges and temperature detectors, interlock features,

and indicating lights as approved by the contracting activity. Type V and VI

clutches shall have indicating lights that show clutch engaged and clutch

disengaged. Also , additional indicating lights shall be as specified in 6.2.

3 4.3 Attachment of mating parts.

3.4.3.1 Securing to shafts. Parts such as sleeves, hubs, plates and flanges

shall be secured to shafts or distance pieces by fitted bolts or shall be splined,

shrunk, or keyed, as applicable

Where such parts are splined or shrunk, retain-

ing nuts shall be employed unless otherwise specified (see 6.2). Nuts used on

through bolts shall be of the self-locking type (see table II).

14

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |