|

|||

|

Page Title:

Tests of production compressors |

|

||

| ||||||||||

|

|  MIL-C-18419B(SHIPS)

the Bureau of Ships. The compressor shall be left

4.5.2 Capacity test methods. -

unassembled pending a decision of the Bureau of

Sh ips .

4.5.2.1 The preferred method for determining

compressor capacity is by the high-pressure flask

4.4.2.5 If no serious wear or other deficiencies

method, by noting the time required to fill a flask of

are noted, these facts shall also be immediately

known volume from zero gage pressure to the rated

communicated to the Inspector of Naval Material

discharge pressure of the compressor. During the

and the Bureau of Ships for information. The com-

time interval required to fill the flasks the compres-

pressor shall be cleaned up, worn parts shall be

sor discharge pressure shall be maintained constant

replaced, and the compressor prepared for ship-

at the rated discharge pressure. The calibration of

ment in accordance with requirements of the con-

the flask volume shall be made in the presence of the

tract.

Government inspector.

4.4.2.6 Within 30 days after successful comple -

4.5.2.1, 1 At the option of the compressor manu-

tion of the preproduction tests copies of a complete

facturer or testing laboratory, the compressor

test report including all recorded data shall be dis -

capacity tests may be in accordance with the ASME

tributed as follows:

Power Test Code (PTC9-1954) as outlined in the sec-

ond edition of the Compressed Air Handbook.

(a) Two to the Bureau of Ships (attention

Code 649).

4.5.3 Test procedures. -

(b) Two to the purchasing activity (if other

than the Bureau of Ships).

4.5.3.1 Electrical .- Motors and controllers

(c) One to the primary inspection of ficer.

shall be tested as required by the applicable specifi -

(d) One to the branch inspection office (if

cations.

any).

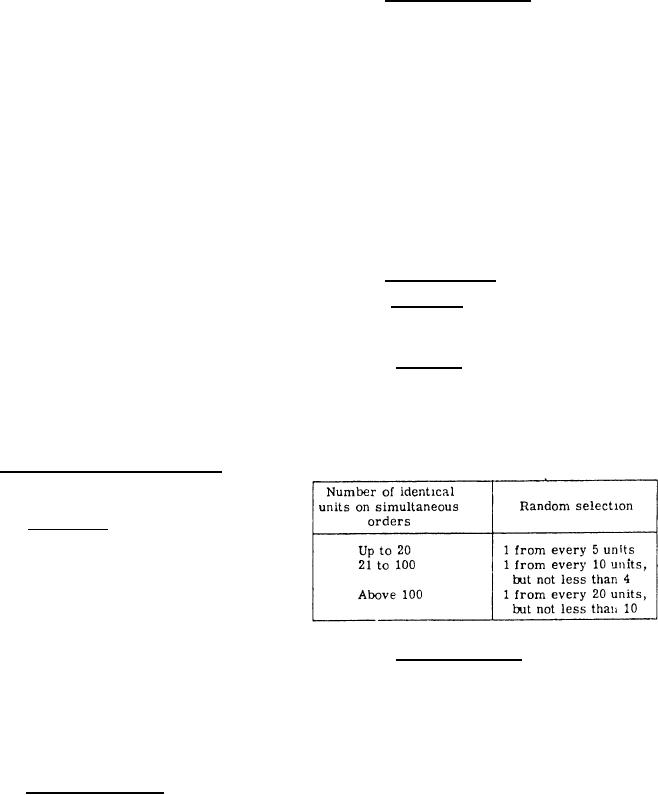

4.5.3.2 Sampling .- Completely assembled com-

4.4.2, 6.1 Bureau of Ships approval of the test

pressors, including driving units, temperature con-

trols, unloading valves, automatic separator drain

report shall be obtained prior to delivery of any air

equipment and all other equipment and fittings shall

compressor of a class covered by the test. A period

be selected for testing in accordance with table III.

of 30 days, after receipt in the Bureau of Ships,

shall be allowed for the Bureau of Ships action.

4.5 Tests of production compressors. -

Table III - Sampling for performance tests.

4.5.1 Hydrostatic and silver brazed Joint tests. -

4.5.1.1 Hydrostatic. - The various parts of

each compressor shall be hydrostatically tested in

accordance with the following:

(a) Cylinders, 1-1/2 times the maximum

designed working pressure.

(b) Water jackets, 265 p.s. lg. for surface

ships, 100 p.s. i.g. for submarines.

(c) Intercoolers, and aftercoolers, 265

4.5.3.3 Performance tests. - Compressor units

p.s. i.g. for surface ships; 100 p.s. i.g.

selected in accordance with table III shall be sub-

for submarines, on the water side and

mitted to a continuous running test of 8 hours duration

1-1/2 times the maximum design work-

at normal capacity and pressure. Test is to be run

ing pressure on the air side.

under normal electrical conditions specified in the

(a) Piping and other parts not mentioned

contract or order. Either phosphate ester or petro-

herein and subjected to pressure shall

leum lubrication may be used during these tests unless

be tested to 1-1/2 times the maximum

a specific requirement is included in the contract or

designed working pressure.

order. Power consumption tests shall be conducted

as a part of the tests. For these tests the data speci-

4.5.1.2 Silver-brazed joints, - All silver-

brazed joints in oil, air and salt water piping shall

fled in 4.5.3.4 shall be recorded at the start and

be tested as required by NAVSHIPS 250-648-8.

19

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |