|

|||

|

|

|||

| ||||||||||

|

|  MIL-C-48550(AR)

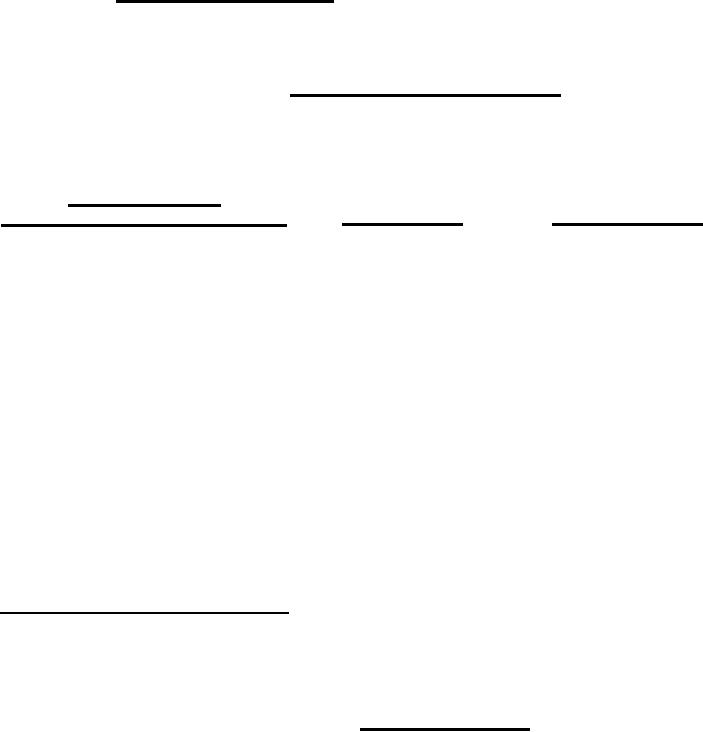

4.3.2.2.1 Sampling inspection. - Examinations and tests shall be

performed on an individual characteristic basis in accordance with

MIL-STD-105, inspection level II of Table I, Sampling Plan Table

II-A, unless otherwise specified under the following tables:

TABLE II. - CLASSIFICATION OF DEFECTS

Vibration and sealing tests shall be performed in that order prior

to the conduct of the other tests in this table.

CHARACTERISTIC

REQUIREMENT

TEST PROCEDURE

MAJOR: AQL 0.65% DEFECTIVE

101.

4.5.1.3

Vibration

304.1.3

102.

Sealing -

3.4.2

4.5.2

3.4.3.1

103.

4.5.3.1

Reticle lean

104.

4.5.3.2

3.4.3.2

Reticle accuracy

105.

Parallax

3.4.3.3

4.5.3.3

106.

Cleanliness

4.5.3.4

3.4.3.4

107.

Reticle illumination

4.5.3.5

3.4.3.5

108.

Elevation travel

4.5.4.1

3.4.4.1

109.

Azimuth travel

3.4.4.2

4.5.4.2

110.

4.5.4.3

Open sight

3.4.4.3

111.

4.5.4.4

Operability

3.4.4.4

3.4.4.5

112.

4.5.4.5

Knob travel

113.

Knob locks

4.5.4.6

3.4.4.6

114.

4.5.4.7

Telescpe alinement

3.4.4.7

115.

4.5.4.8

Azimuth fine adjustment

3.4.4.8

116.

Fastening Devices

4.5.4.9

3.4.4.9

117.

Carrying handle

4.5.4.10

3.4.4.10

4.5.4.11

118.

Strap security

3.4.4.11

119.

4.5.4.12

Gasket

3.4.4.12

MINOR:

AQL

4.0%

DEFECTIVE

Visual

201.

3.3.2(e)

Locking compound screw

heads

Visual

202.

Paint finishes

3.3.2(c)

TABLE III. - SPECIAL SAMPLING

One collimator shall be selected at random from each 50 produced.

Samples shall meet all the requirements of Tables II subsequent to

the conduct of the following examinations and tests, except Char-

acteristics 101 (Vibration), 117 (Carrying handle), 118 (Strap sec-

urity) shall be performed prior to 403 (Rain).

TEST PROCEDURE

CHARACTERISTIC

REQUIREMENT

4.5.1.1

401.

3.4.1.1

Storage temperature

4.5.1.2

402.

Operating temperature

3.4.1.2

4.5.1.4

3.4.1.4

403.

Rain

7

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |