|

|||

|

|

|||

| ||||||||||

|

|  MIL-C-48868E (AR)

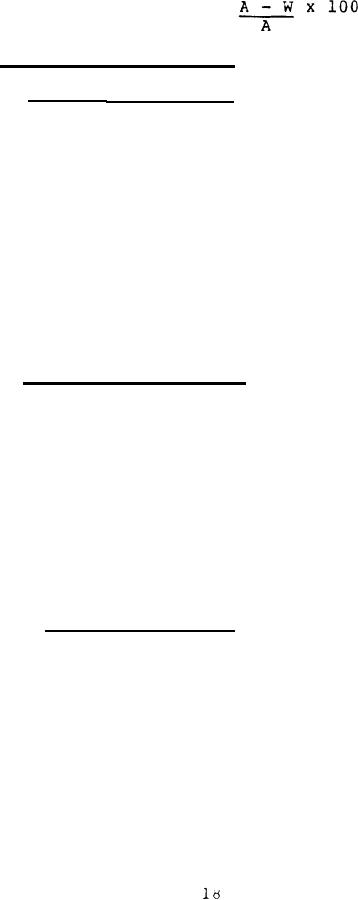

Percent (%) Total Volatiles =

4.5.1.3 Analytical procedure.

4.5.1.3.1 Solvent extraction. Using a tared, extracoarse,

sintered glass thimble, extract each sample from 4.5.1.2, with

methylene chloride, for a minimum of 16 hours in a Roweg

extractor (MIL-STD-286 Method 104.1.3). Evaporate the extract

to dryness, using a current of clean, dry air. This extract is

to be used for diphenylamine determination in 4.5.1.3.2. Dry

the residues (non-extractable material) in the extraction

thimbles by aspirating the thimble and contents until the odor

of methylene chloride is not discernible. Dry the thimble plus

residue for 1/2 hour minimum at 100 2C. Cool in a

desiccator (1/2 hr. min.). Determine the dry weight of this

residue (Weight C) to the nearest 0.2 mg. as the difference

between this weight and the weight of the empty thimble. This

residue is to be used for the nitrocellulose determination in

4.5.1.3.3.

4.5.1.3.2 Diphenylamine (DPA). To the dried extract from

4.5.1.3.1 add 50 milliliters (ml.) of glacial acetic acid. If

necessary, warm slightly to dissolve the extract, then cool to

room temperature. Complete the determination of diphenylamine

in the solution according to Method 201.1.4 (starting with

paragraph 5.5) of MIL-STD-286 except that 25 ml. of methylene

chloride is to be added after addition of the potassium iodide

solution.

When the end point appears to have been reached,

(absence of blue color) the flask is stoppered and shaken. If

no color appears, the end point has been reached; otherwise,

continue titration until the blue color is discharged and shak-

ing produces no further color. Calculate the percent DPA as

shown in MIL-STD-286, Method 201.1.4, paragraph 5.13.

4.5.1.3.2.1 Alternate method. Cut 1.0 to 1.1 grams of

sample in to 1/4 inches squares or smaller. Dry in microwave

moisture analyzer. Transfer the dried sample to a weighing

bottle. Cool the sample to room temperature in a desiccator

and weigh. Transfer the sample to a square homogenizing

beaker. Reweigh the empty weighing bottle. The sample weight

is equal to the total weight minus the weight of the empty

weighing bottle. Add 50 ml of 90% methanol to the square

beaker. Agitate the sample/solvent mixture in the hot

ultrasonic bath for 10 minutes. Homogenize the mixture using a

Binkmann homogenizer (or equivalent) for 2 minutes or until the

sample is completely defiberized. Transfer the mixture to a

filtering apparatus fitted with a suitable filter paper.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |