|

|||

|

Page Title:

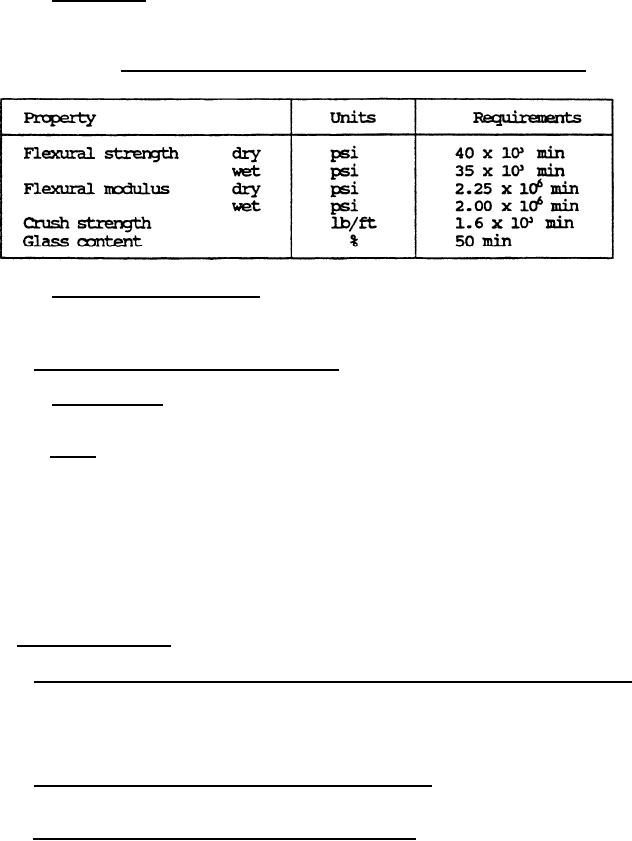

Table II. Physical requirements of Plastic support pole body. |

|

||

| ||||||||||

|

|  MIL-C-52765E(ME)

3.4.2.1 Pole body. The plastic pole body material shall be as specified in

the applicable drawings and shall meet the physical requirements as specified

in table II.

TABLE II. Physical requirements of Plastic support pole body.

3.4.2.2 Plastic pole assembly. Connector and end reinforcments, when

applicable, shall be permanetly attached to the pole body. the method of

attachmenbt shall meet the requirements specified herein.

3.4.3 Support pole, type I and type II.

3.4.3.1 Column load. When tested as specified in 4.5.2.1.3.1, a 4-section

pole shall support a 300-pound axial load for 60 seconds.

3.4.3.2 Drop. When tested as specified in 4.5.2.1.3.2, the support poles

shall sustain no damage which inhibits assembly or disassembly with a 1.568

OD/1.565 ID gauge. The type I support PolesShall show no slippage of the

sleeve into the pole body more than 0.25-inch. The type II supprt pies

shall shcw no evidence of fiberglass fibers exposed or protruding out of

resin, failure of the joint section, chips more than 0.25-inch deep, or cracks

in the pole body. Cracks which only appear to be superficial shall be

sujected to the column load test specified in 4.5.2.1.3.1 to establish

conformance of the pole. The Cracked joint shall be positioned near the

Center of the column.

3.5 Batten spreader.

3.5.1 Fiberglass reinforced plastic (FRP) batten spreader

(subtype A). The

FRPbatten spreader shall vonform to the applicable drawings

and as specified

herein. The color pigment for class 2 batten spreaders shall

be a white paste

or pigment and shall be added to the resin mix not more than

8 parts nor less

than 1 part per hundred of the base resin.

3.5.2 Thermoplastic batten spreader (subtype B). The termoplastic batten

spreader shall confor to ht eapplicable drawings, and as specified herein.

3.5.3 Batten spreader, shbtype A and subtype B.

6

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |