|

|||

|

|

|||

| ||||||||||

|

|  MIL-C-52972A(ME)

TABLE I.

Examination schedule. (Cont'd)

Defects

Requirements paragraph

3.12

114.

Instruments and controls missing or not as

specified.

115.

3.8.2

Tubing not as specified.

Lubrication provisions or tags missing or not

3.14 thru 3.14.6

116.

as specified.

117.

Fungus and moisture resistance not as specified.

3.15

Slinging and tiedown provisions not as specified.

3.16

118.

Identification marking missing or not as speci-

3.17

119.

fied.

3.17.1

120.

Instruction plates missing or not as specified.

3.17.2

Treatment and painting not as specified.

121.

3.18 thru 3.18.7

Workmanship not as specified.

122.

3.18.3, 3.18.4

Welding not in conformance with codes and

123.

certifications.

3.18.8.2, 4.5.2.10

124.

Air purity test not meeting specifications.

4.5.2 Tests.

4.5.2.1 Test conditions. Prior to test, the compressor shall be lubricated

with military oils and greases. Oils shall be those designated for use in

ambient temperatures at place of test. The compressor unit shall operate as

specified herein without maintenance other than the contractor's recommended

normal scheduled maintenance as established by a maintenance schedule prepared

and submitted by the contractor prior to test. Unless otherwise specified

herein, tests shall be conducted with all compressor unit components and

accessories, including the air intake extension, installed and functioning

normally. Capacity shall be determined in accordance with the ASME Performance

Test Code (PTC-9) or by calculating capacity based on weight of air delivered in

a given time. Condensate removed from the air shall not be included as part of

the compressor capacity. If the weight method is used, the reservoir (minimum

volume 1000 cubic inches) shall be filled to 2000 plus or minimum 100 psig, and

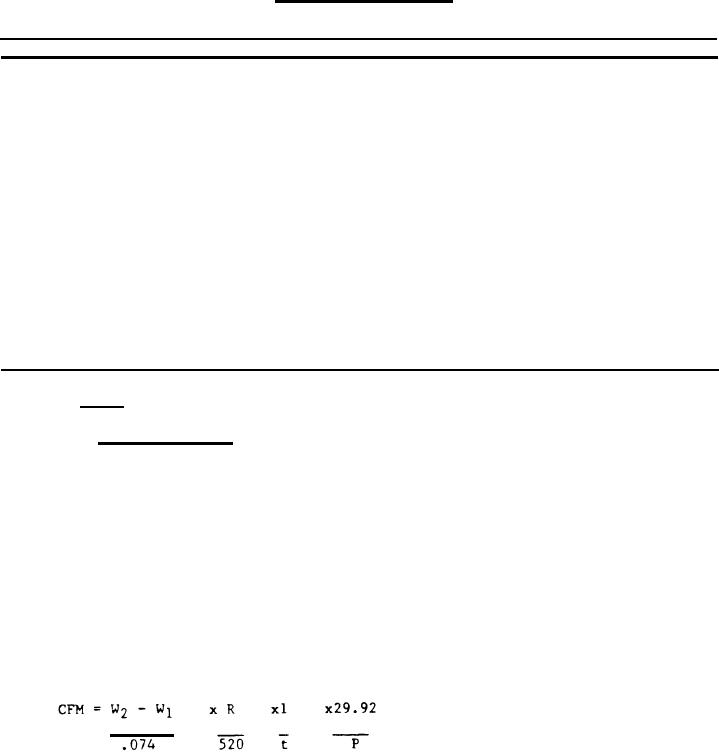

the capacity shall be determined by the following formula:

=

Cubic feet per minute (free air)

Where: CFM

W1

=

Empty weight of capacity check assembly (lb.)

W2

=

Full weight of capacity check assembly (lb.)

R

=

Air temperature at cooling fan in degrees, Rankline (Farenheit,

absolute)

= Time required to fill resevoir in minutes

t

= Barometric pressure in inches, Hg.

P

16

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |