|

|||

|

Page Title:

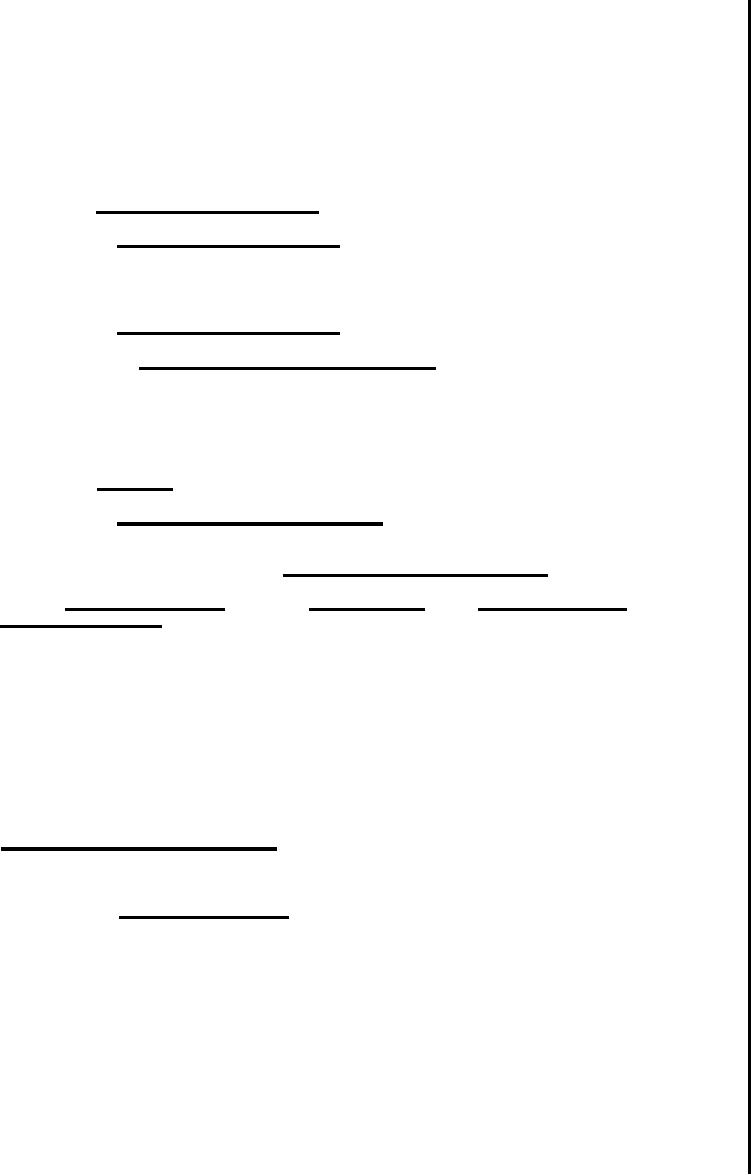

Table II. Classification of defects. |

|

||

| ||||||||||

|

|  MIL-C-70490(AR)

4.3 Inspection provisions.

4.3.1 Submission of product. Unless otherwise specified by

the contracting officer, inspection lot size, lot formation, and

presentation of lots shall be in accordance with "Submission of

Product" provision of MIL-STD-105.

4.3.2 Examination and tests.

4.3.2.1 Components and subassemblies. All components and

subassemblies shall be inspected in accordance with the inspection

provisions contained in Quality Assurance Provisions (QAP's)

listed in the Technical Data Package (TDP). In the absence of

QAP's, the applicable Quality Assurance Provisions of MIL-F-13926

shall apply.

4.4

Sampling.

4.4.1 Environmental/performance. The memory shall be

inspected to the requirements in Table II.

TABLE II.

Classification of defects.

No.

Characteristics

Requirement

Test procedure

100% Inspection

4.6.3

Memory read cycle

3.2.1.1

1.

4.6.4

RAM write cycle

2.

3.2.1.2

4.6.5

EPROM program cycle

3.2.1.3

3.

4.6.6

4.

EPROM erasure

3.2.1.4

4.6.7

RAM standby circuitry

3.2.1.5

5.

Common connector contact

6.

4.6.8

3.2.1.6

continuity

Pullup resistor

4.6.9

7.

3.2.1.7

4.6.1

ESS temperature

3.3.2

8.

4.6.2

ESS vibration

3.3.3

9.

MAJOR:

AQL 1.0% Defective

Workmanship

3.6

4.6.10

101.

4.4.2 Special sampling. One memory shall be selected at

random as a special sample from each lot or each 100 produced

which ever occurs first. The sample shall meet the requirements

and tests in Table III.

12

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |