|

|||

|

Page Title:

Table II. Vehicular electrical system. (cont) |

|

||

| ||||||||||

|

|  MIL-D-435F(ME)

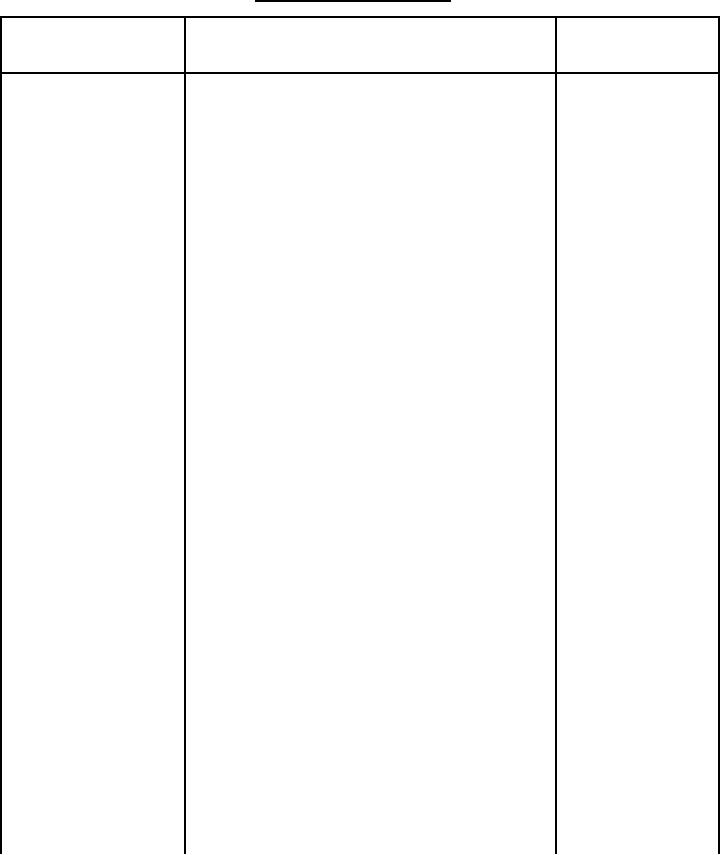

TABLE II. Vehicular electrical system. (Continued)

Description

Requirements

Quantity Per

heater

Wiring

Heavy duty type.

AR

Wire identification

SAE J560 or J821

AR

Wiring harness

Polyethylene electrical conduit, each end

AR

weatherproofed with silicone sealant or with

one-half over-lapping turns of plastic electrical

tape.

Provided where needed along the wire routing to

Grommets

AR

prevent chafing.

Elastomer cushioned support straps or elastomer

Supports

AR

ties with mounts; wiring support spacing 36 in

max span, prevent whipping, chafing, and

fatigue damage.

Wiring splices

Mechanical splicing devices; interior

AR

waterproofed with silicone lube or compounds.

Connectors and

Waterproof types; blade type SAE J858, pin type AR

terminal

SAE J928, and spade SAE J561. Blade and pin

types fully enclosed and lubricated, prior to

assembly with silicone lubricant; spade type

equipped with heat shrinkable sleeves and coated

with electrical varnish after assembly; all

connectors and terminals plated or solder-coated

to retard corrosion.

Connector holder

Plastic or plastic-insulated metal spring clips;

1 ea per connector

fastened to vehicle; furnished to anchor

wire-to-wire connectors.

Running lamps

4 sidemarker, 4 clearance, 3 rear identification;

11 ea min

per TTMA RP-108/1 or RP-108/3. Waterproof

and shock resistant types.

12

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |