|

|||

|

Page Title:

Table V. Summary of required weld tests. |

|

||

| ||||||||||

|

|  MIL-E-19141D

4.2.5 Inspection criteria. The samples selected in accordance with 4.2.4

shall be subjected to the examination of 4.3, the weld metal tests specified in

table V, and the tests specified in table VI.

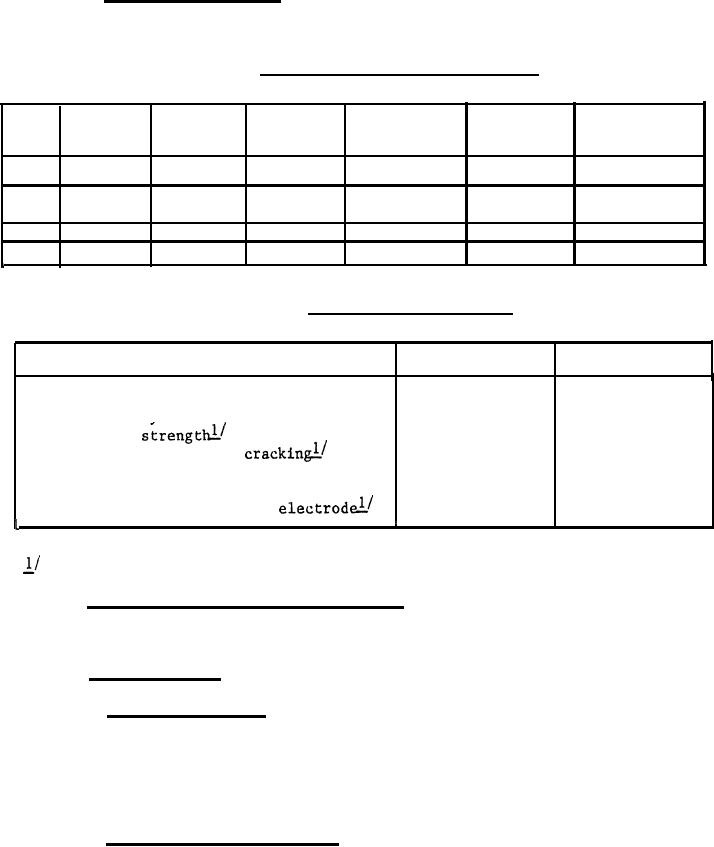

TABLE V. Summary of required weld tests.

Macro-

Surface

Requirements

Procedures

examination

soundness

Chemical

Hardness

Size

Table IV

4.4.7

x

All

3*7

4.4.5

x

All

4.4.6

3.4

4.4.5

x

All

3.5

4.4.5

x

All

Summary of other tests.

TABLE VI.

t

Requirements

Procedures

Tests

3.3

4.4.2.1

Diameter and length of core wire

3.2.2

4.4.2

Concentricity

3.2.3

4.4.3

Dielectric

3.2.4

4.4.4

Covering, flaking and

4*4.8

3.2.9

Covering moisture

3*3.4

4.4.9

Alloy identity - core wire

4.4.9

3.3.5

Alloy identity - finished

I

I

When specified (see 6.2.1).

4.3 Visual and dimensional examination. Each of the sample electrodes

selected in accordance with 4.2.4 shall be examined to verify conformance with

all requirements which do not involve tests specified in 4.4.50

4.4 Test procedure.\

4.4.1 Welding equipment. Welding machines used for supply power for

testing electrodes shall be variable voltage direct current (d.c.) motor-

generator type, variable voltage d.c. rectifier welder, or a.c. welding trans-

former conforming to NEMA EW 1. The power source shall be of sufficient rating

to supply current demanded by the electrode type and size under test. Open

circuit voltage shall not exceed 80 V.

4.4.2 Concentricity measurement. Measurement of the prepared electrode

is made with the aid of a supplemental piece of 1/4 by l/4-inch key stock

(or equal) 2 + l/16-inch long. The key stock shall be placed symmetrically

across the groove and, using any instrument, the core wire diameter plus the

thickness of the cover on one side of the electrode plus the thickness of the

key stock shall be measured. For instruments using a base for zero reference,

the base where it is in contact with the electrode during measurement shall be

9

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |