|

|||

|

|

|||

| ||||||||||

|

|  MIL-E-22200G

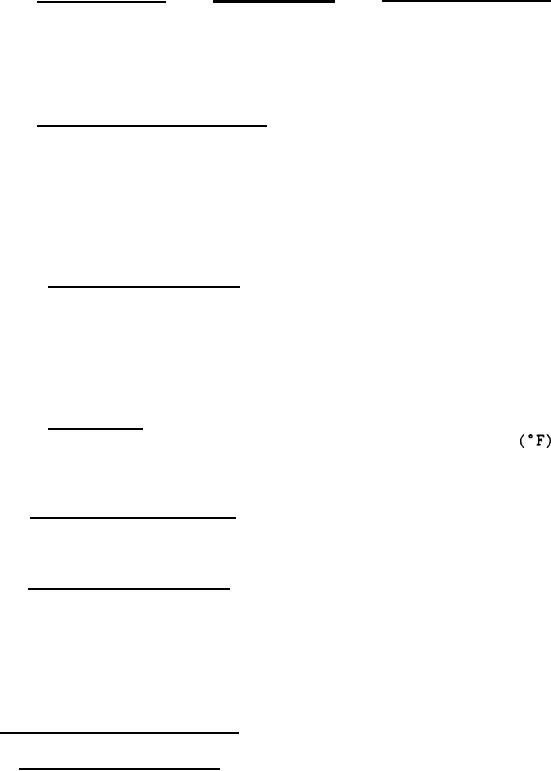

Distance from grip

end to full thick-

ness of covering

Bare portion,

(max)

(min)

Electrode size

1-1/4 inches

5/32

inch

1/2 inch

and

smaller

1-1/2 inches

3/4 inch

3/16

inch

and

larger

Electrode identification.

3.5.10

3.5.10.1 Marking. At least one legible electrode type designation or

classification number (see 3.1) shall be applied to the electrode covering in

such a manner that at least one complete type designation shall come within the

space 2-1/2 inches from the grip end of the electrode. The prefix "MIL-" may be

omitted from the type designation. When specified (see 3.1), each electrode

shall also be marked with heat or lot identification.

3.5.10.2 Size and legibility. The imprinted designations shall be composed

of equal-size block characters, the height of which shall be 50 to 100 percent of

the overall electrode diameter (core wire plus covering) but need not exceed a

5/32 inch height. The imprinted designations shall read from the grip-end to the

arc end. The color of the print shall contrast the color of the electrode

covering and printed designations shall be readable under normal lighting

conditions.

3.5.10.3 Stability.

Printed type designations shall remain discernible on

electrodes rebaked at temperatures up to 850 degrees Fahrenheit

and on

unused portions of partially consumed electrodes or discarded stubs, and shall

resist effacement by contact incidental to normal handling, shipping and storing.

3.5.11 Covering composition. The chemical composition of the coverings

except iron powder and moisture is optional with the manufacturer. Moisture and

iron content, when required, shall be as specified (see 3.1, 4.6.8, and 4.6.9).

3.5.12 Production equipment. When a change is made in a production run of

one MIL-type electrode to another, inspection shall be performed prior to start-

ing the new run to assure that equipment and process lines are purged of material

from the previous production run. This inspection shall be performed for all

equipment used in manufacturing operations where the material is not segregated

and positively identified, for example cutting to length, extruding, baking and

so forth.

3.6 Core wires of electrodes.

3.6.1 Core wire dimensions.

Standard core wire diameters and lengths of

electrodes shall be as specified (see 3.1). The diameter of the core wire shall

vary not more than plus or minus 0.003 inch. The length shall vary not more than

plus or minus 1/8 inch.

5

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |