|

|||

|

|

|||

| ||||||||||

|

|  MIL-E-22200G

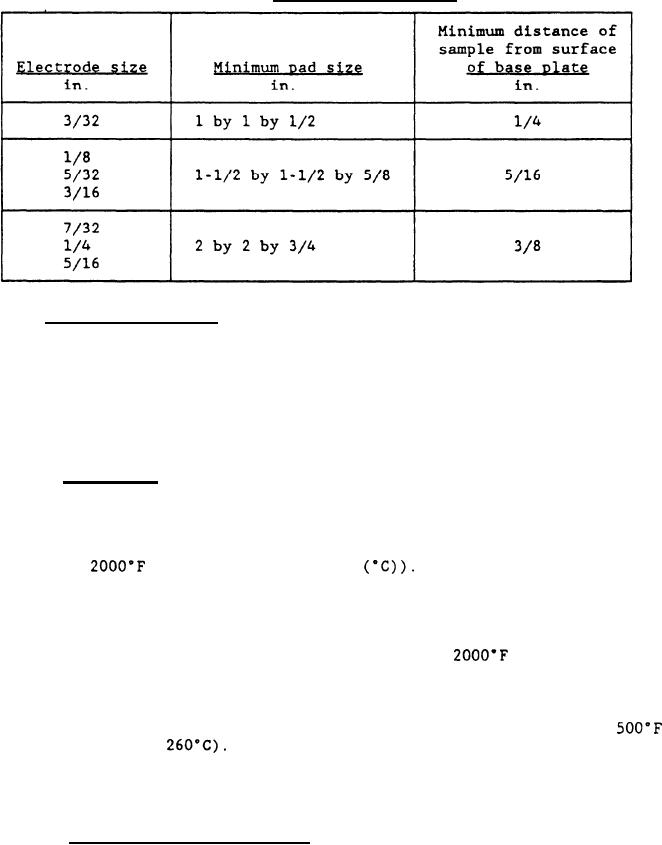

Weld pad dimensions.

TABLE I.

4.6.8 Covering moisture. The following method shall be used to determine

moisture content in an electrode covering: Oxygen shall be passed over the

sample of covering in a nickel or clay boat placed in a fused silica or high-

temperature ceramic-type combustion tube which is then heated. Liberated water

shall be collected in a weighted absorption U-tube and weight of water determined

by the increase in the weight of the U-tube. The moisture content shall be

expressed as a percentage of the weight of the covering sample. Electrodes shall

meet the minimum moisture requirements as specified in the detail specification.

4.6.8.1 Apparatus.

The apparatus shall be as shown on figure 2 and shall

consist of the following:

(a)

A tube furnace with a heating element of sufficient length to heat

at least 8 inches of the middle portion of the combustion tube to

(1093 degrees Celsius

(b)

An oxygen purifying train consisting of a needle valve, flow

meter, 96 percent sulfuric acid wash bottle, spray trap, and

anhydrous magnesium perchlorate drying tower.

(c)

Fused silica combustion tube 7/8 inch inside diameter with plain

ends and a devitrification point above

(1093"C).

(A high-

temperature ceramic-type tube can be used, but a higher blank

value will result.) A plug of fine glass wool to filter the

gases shall be inserted far enough into the exit end of the

combustion tube to be heated to a temperature of 400 to

(204 to

(d)

Water absorption train consisting of a U-cube (Schwartz type)

filled with anhydrous magnesium perchlorate and a concentrated

sulfuric acid gas-sealing bottle.

4.6.8.2 Preparation of the sample. The covering sample of at least 4 grams

shall be a composite of the middle portions of covering from three electrodes

from the same package and shall be removed by bending or with clean, dry forceps.

The sample shall be transferred immediately to a dried, stoppered vial or sample

bottle.

15

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |