|

|||

|

|

|||

| ||||||||||

|

|  MIL-E-24763A(SH)

w/INT. AMENDMENT 1

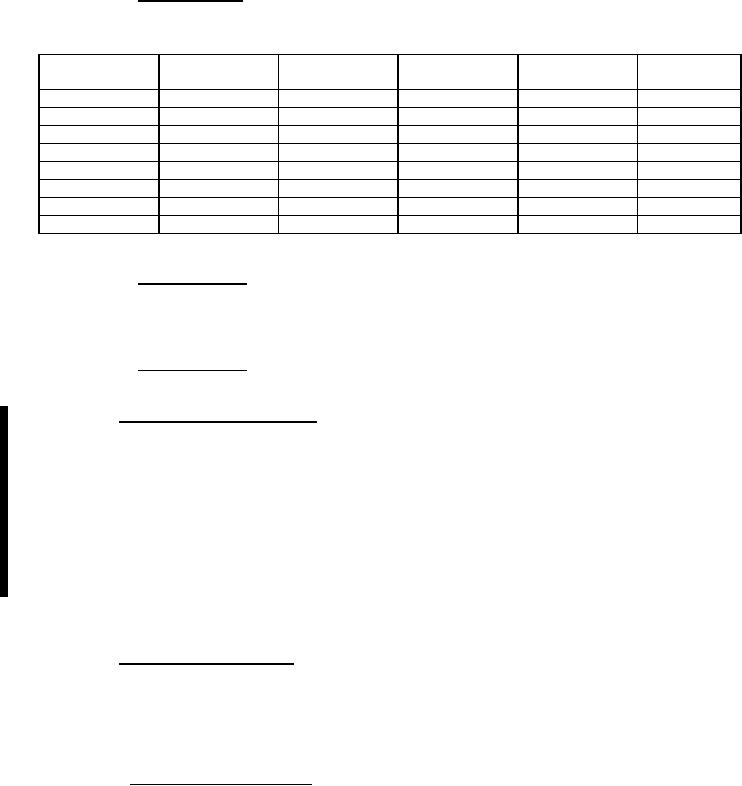

3.8.11. Impact resistance. The enamel when tested in accordance with 4.6.16 shall not exceed the

maximum percent area increase accommodated by the enamel without cracking or other failure as specified for each

spherical segment with the following:

Spherical

End

Base Diameter

Segment

Segment

Max % Area

Segment

Radius

Elevation

Increase

1

A

0.375

0.194

0.146

60

2

A

0.375

0.208

0.119

40

3

A

0.375

0.252

0.084

20

4

A

0.375

0.326

0.059

10

5

B

0.375

0.440

0.042

5

6

B

0.375

0.676

0.027

2

7

B

0.375

0.947

0.019

1

8

B

0.375

1.332

0.013

0.5

3.8.12. Directions for use. The manufacturer must provide written directions for the mixing and applying

of the enamel supplied and this direction shall include all information necessary to comply with OHSA Hazard

Communication Standard and FED-STD-313. In addition, the manufacturer must prepare an ASTM F718 data sheet

with separately details requirements for small unit (pint, quart, and gallon) and large unit (5 gallon) containers.

3.8.13. Compatibility test. When tested in accordance with 4.6.17, the dried enamel film shall not show

any visual difference in color and gloss, and no streaks, craters, or pigment flowing.

3.9 Batch specific VOC certification. Manufacturer shall prepare container label instructions for the

enamel in accordance with the requirements of 29 CFR 1910, 1915, 1917, 1918, 1926 and 1928 - Hazard

Communication (see 6.8). To comply with the Environmental Protection Agency (EPA) National Emission

Standards for Hazardous Air Pollution (NESHAP) requirements for shipbuilding and ship repair, the following

two statements must appear on each paint can label:

a. A certification that the paint in the container meets the NESHAP requirements for shipbuilding and

ship repair.

b. A statement of the ratio of volatile content to solids expressed as grams of volatile organic

hazardous air pollutants (VOHAP) per liter of solids.

4. QUALITY ASSURANCE PROVISIONS

4.1. Responsibility for inspection. Unless otherwise specified in the contract or purchase order, the

contractor is responsible for the performance of all inspection requirements (examinations and tests) as specified

herein. Except as otherwise specified in the contract or purchase order, the contractor may use his or her own or any

other facilities suitable for the performance of the inspection requirements specified herein, unless disapproved by

the Government. The Government reserves the right to perform any inspections set forth in this specification where

such inspections are deemed necessary to ensure supplies and services conform to prescribed requirements.

4.1.1. Responsibility for compliance. All items shall meet all requirements of sections 3 and 5. The

inspection set forth in this specification shall become a part of the contractor's overall inspection system or quality

program. The absence of any inspection requirements in the specification shall not relieve the contractor of the

responsibility of ensuring that all products or supplies submitted to the Government for acceptance comply with all

requirements of the contract. Sampling inspection, as part of the manufacturing operations, is an acceptable practice

to ascertain conformance to requirements; however, this does not authorize submission of known defective material,

either indicated or actual, nor does it commit the Government to accept defective material.

13

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |