|

|||

|

|

|||

| ||||||||||

|

|  MIL-E-24763A(SH)

w/INT. AMENDMENT 1

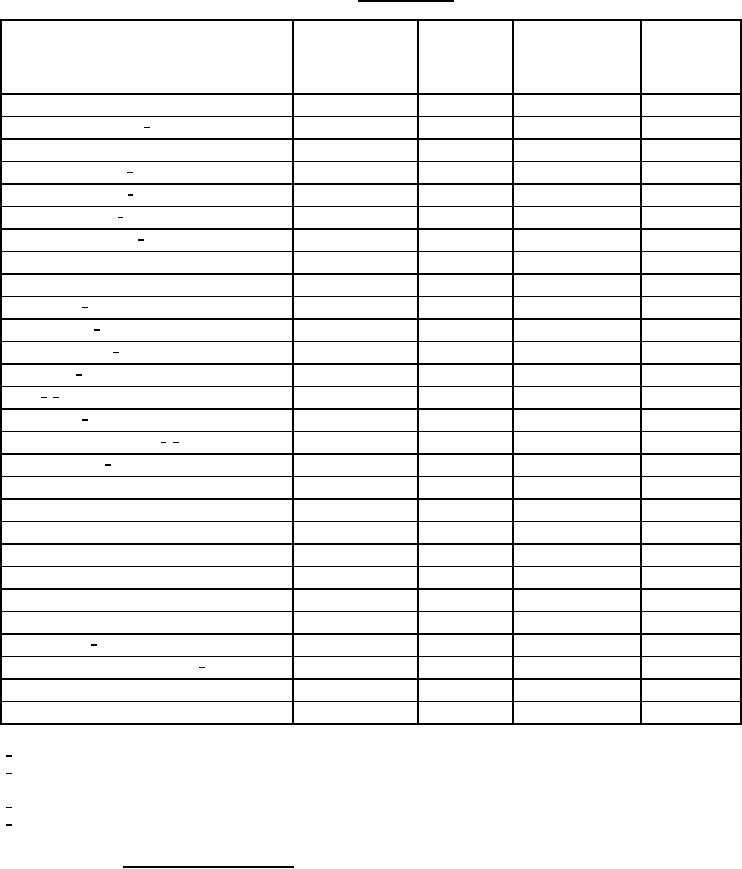

TABLE V. Test procedures.

Applicable

test method

ASTM test

Characteristic

Requirements

Test

FED-STD-

method

141

Material requirements

3.6

----

D3168

----

Condition in container1/

3.8.1

3011.3

----

----

Storage Stability

3.8.4

3021.1

----

4.6.1

Spraying properties1/

3.8.5

4331.2

----

4.6.2

Brushing properties1/

3.8.6

4321.3

----

4.6.3

Rolling properties1/

3.8.7

4335

----

4.6.4

Color/color deviation1/

3.7.1

----

E97, D2244

4.6.5

Flexibility

Table IV

6221

----

4.6.6

Knife Test

3.8.8

6304.2

----

4.6.7

Consistency1/

Table IV

----

D562

4.6.10

Sag resistance1/

Table IV

----

D4400, Method A

----

Fineness of grind1/

Table IV

----

D1210

----

Flash point1/

Table IV

----

D3278

----

VOC1/ 4/

Table IV, 3.7.3

----

----

4.6.8

Drying time1/

Table IV

4061.3

----

----

Gloss 60-degree specular1/ 2/

Table IV

----

D523

4.6.18

Coarse particles1/

Table IV

----

D185

----

Impact resistance

Table IV

----

D2794

4.6.16

Lead content

Table IV

----

D3335

----

Resistance to biological growth

3.8.2

----

D3274, D3273

4.6.9

Freeze-thaw stability

3.8.3

----

D2243

4.6.10

Primer compatibility

3.8.9

6301.3

D3359, Method A

4.6.11

Enamel recoatability

3.8.10

----

----

4.6.12

Accelerated weathering

3.7.2

----

----

4.6.13

Contrast ratio3/

Table IV

----

D2805

4.6.19

Soluble and total metal content 4/

3.5

----

----

4.6.14

Long term exterior exposure

3.7.4

----

----

4.6.15

Compatibility

3.8.13

----

----

4.6.17

Notes:

1/

Required for quality conformance inspection test.

2/

Make a 3 mil wet film thickness drawdown on glass, dry for 168 hours at ambient laboratory conditions before

performing test.

3/

Spreading rate shall be such as to yield a dry film thickness of 3 to 4 mils.

4/

By data certification

4.6.1.3. Accelerated storage stability. After exposure to a temperature of 60C (140F) continually for 30

days, a new unopened full 1-quart can of enamel shall be examined for compliance with 3.8.4.3.

16

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |