|

|||

|

|

|||

| ||||||||||

|

|  MIL-F-24702(SH)

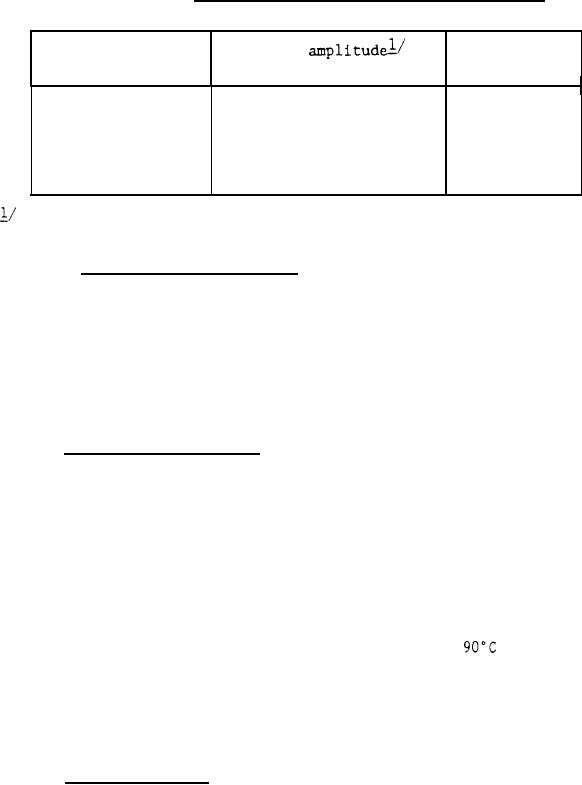

intervals of 1 Hz, at the amplitudes shown in table III. At each frequency, the

vibration shall be maintained for times shown in table III, An acceptable

alternative will be a continuous sweep from 4 to 50 Hz, over a period of at least

1 hour, with the amplitudes shown in table III.

TABLE III. Vibr atory displacement single amplitude.

Time

Frequency range

Table

(inches - minimum)

(Hz)

(minutes)

4

to

15

0.05

2

16

to

25

.04

1

26

to

33

1

.03

34

to

40

.02

1

41

to

50

.01

1

For Government conducted tests, the maximum amplitude shall not

exceed the minimum required amplitude by more than 20 percent.

4.7.6.3 Media migration analysis. The port blanks shall be removed and the

filter and housing shall be flushed with 3000 milliliters (mL) minimum of

prefiltered fluid and the effluent collected. The effluent shall be filtered

through a membrane filter disk, 47 millimeters (mm) diameter, absolute 0.8

micrometer, type AA Millipore, or equal, which has been previously washed with

prefiltered solvent, The membrane from this analysis and the membrane retained

from the degree of filtration test (see 4,7.2) shall be examined for evidence of

filter media migration. There shall be no media migration identifiable as coming

from the filter element medium.

4.7.7 Materi al compatibility. Elements 4, 5, and 6 shall be tested for

compatibility with fluid conforming to MIL-H-19457, MIL-H-22072 and MIL-H-17672

One patch (four required; each approximately 2 by 4 inches) of the filtration

media shall also be tested for compatibility with each of above fluids. An

untested fourth patch shall be retained for microscopic comparison with the

immersed patches on completion of the tests. Test patches shall be taken from a

single representative specimen of filtration media (approximately 8 by 4 inches)

Each test fluid shall be thoroughly mixed with 5 percent water prior to testing,

and stirred approximately every 24 hours thereafter, weekends excepted.

During

the test, water and fluid may be added as necessary to make up evaporation

losses.

Elements and testpatches shall be completely immersed in appropriate

test fluids as designated above, for 195 hours at 85 to

After immersion

and decreasing of the elements and patches, there shall be no visible evidence of

degradation or corrosion. Element bubble points shall be not less than 85

percent nor more than 120 percent of the bubble point at the beginning of the

test. Patches shall be compared to the untested specimen under a microscope and

visible difference noted.

4.7.8 Additional tests. After the fluid compatibility tests, element

numbers 4, 5, and 6 may be subjected to any of the tests listed for element

numbers 1, 2, or 3 and shall satisfactorily pass those tests. Tests to be

conducted and elements selected shall be at the discretion of NAVSEA or its

representative.

10

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |