|

|||

|

|

|||

| ||||||||||

|

|  MIL-F-600020(MU)

4.2.3 Rejection. If any assembly `r

tual requirements. Severity of Government

inspection of individual characteristic will

component fails to comply with the applica-

ble requirements, the initial production

be directly related to the seriousness of the

sample shall be rejected. In the event of

classification assigned. In no instance will

a characteristic classified "critical" be ac-

rejection, the Government reserves the right

to require the contractor to take corrective

cepted soley on the basis of the contractor's

action' and submit new or supplemental

records.

quantities until such time as an acceptable

sample is submitted, or until otherwise di-

4.2 Initial production inspection.

rected by the contracting officer.

4.3 Inspection provisions.

4.2.1 Submission. Prior to normal pro-

duction the contractor shall submit an initial

4.3.1 Lot formation. A lot shall consist

production sample consisting of (*)

of parts produced by one manufacturer in

consecutively produced assemblies and com-

one unchanged process, in accordance with

plete sets of parts (i.e. 50 each of every

the same drawing, same drawing revision,

individual component and subassembly),

same specification, and same specification

which have been produced by the produc-

revision. Drawing, specifications, and proc-

tion process which the contractor been use

ess changes not affecting safety perform-

in f fulfilling the contract, to a Government-

ance or fit, as determined by the Govern-

approved facility designated by the con-

ment shall not necessitate changing the lot

tracting officer. All parts and materials

number.

shall be obtained from the same source of

supply as will be used in regular production.

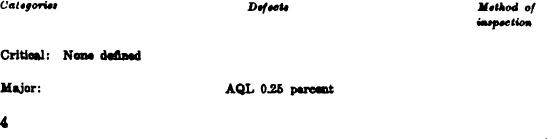

4.3.2 Examination. Sampling plans and

The initial production sample shall be ac-

procedures for the following classifications

companied by certificates of analyses for

of defects shall be in accordance with Stand-

all materials A sample l -hmll also be sub-

----- ----

ard MIL-STD-165D except that inspection

mitted whenever a change occurs in manu-

for critical defects, when listed, shall be

facturing process, material used, drawing,

100 percent. Continuous sampling plans in

specification, or source of supply such as to

accordance with Standard MIL-STD-1235

significantly affect product uniformity as

may be used if approved by the procuring

determined by the Government.

activity. Also, at the option of the procur-

ing activity, AQL's and sampling plans may

be applied to the individual characteristics

4.2.2 Inspections to be performed. Each

listed using an AQL of 0.26 percent for

assembly and component shall be inspected

each major defect and an AQL of 0.40 per-

by the Government for all the inspection

cent for each minor defect. Equipment

specified in 4.3.2 and 4.8.9 of this specifi-

necessary for the performance of the in-

cation and for all additional requirements

spections listed shall be in accordance with

of the applicable drawings.

4.8.4.

4.6.2.1 Gasket (see dwg.) 8866649 covering a detail of dwg. 8866648

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |