|

|||

|

Page Title:

Plating thickness test (drop test) |

|

||

| ||||||||||

|

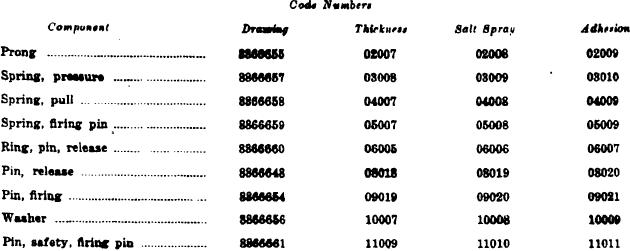

|  4.3.3.4 Plating of components (see ap-

ness, environmental, and acceptance criteria

plicable drawing). For each component de-

as applicable shall be as modified herein. In

termination of compliance with the applica-

all tests actual components shall be used

ble requirements for plating shall be in ac-

(separate panels or specimens are not per-

cordance with the provisions of Standard

MIL-STD-171, except that sampling, thick-

mitted).

4.3.3.4.1 Plating thickness test (drop

4.3.3.4.3 Plating adhesion test -- Major

test) -- Major defect. A random sample of

defect. A random sample of five units shall

five units shall be selected from each lot of

be selected from each lot of plated compo-

plated component for this test. A mini-

nents for this test. Failure of one or more

mum of four readings shall be taken on each

sample units to comply with the applicable

unit. If this minimum plating thickness on

requirement shall be cause for rejection.

any single article is less than 70 percent of

The test shall be performed using equipment

the specified thickness, (0.00015 inches) the

in accordance with 4.3.4.

lot shall be rejected. The minimum thick-

ness measured on each article shall be re-

corded, and the average value computed by

4.3.3.5 Surface treatment of components

dividing the sum of the minimum thick-

(ace applicable drawing) -- Major defect.

nesses by five. If the average minimum

A random sample of five units shall be se-

thickness is less than the specified thickness

lected from each lot of treated components

the lot shall be rejected. The test shall be

for this test. Failure of one or more sample

performed using equipment in accordance

with 4.9.4.

units to meet the requirements shall be

cause for rejection. For aluminum parts

4.3.3.4.2 Salt spray test -- Major defect.

the corrosion resistance test in accordance

A random sample of five units shall be

with Specification MIL-A-5625A shall be

selected from each lot of plated components

performed. For zinc parts the salt spray

for this test. Failure of one or more sam-

test in accordance with Specification MIL-

ple units to meet the applicable requirement

T-12879 shall be performed. In all tests

shall be cause for rejection. The teat shall

be performed as specified in 4.4.4 using

actual components shall be used (separate

equipment in accordance with 4.3.4.

panels or specimens are not permitted).

14

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |