|

|||

|

Page Title:

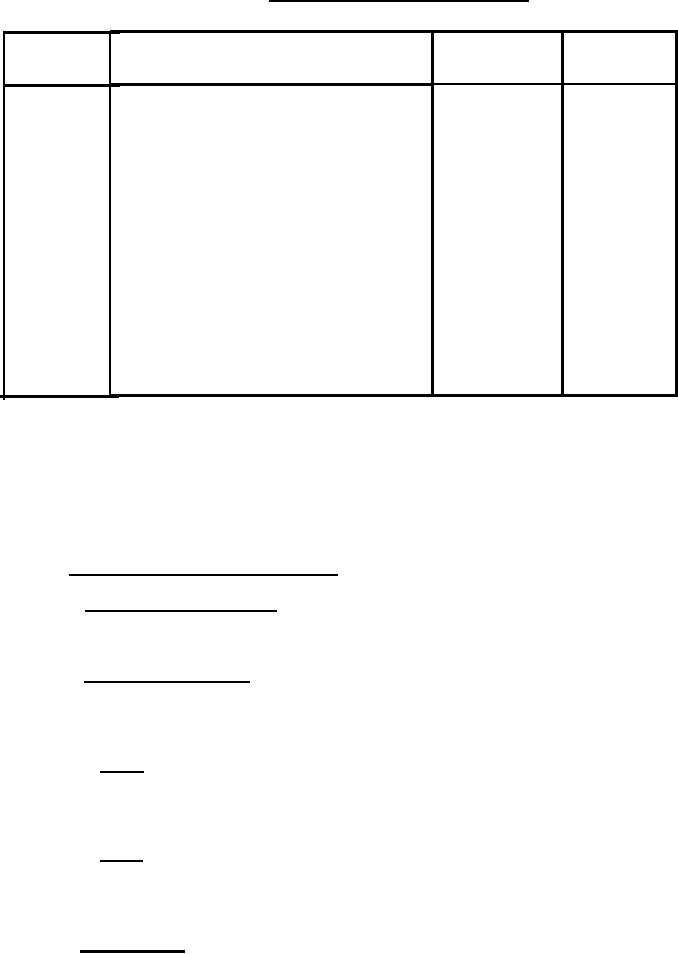

Table II. Quality conformance inspection |

|

||

| ||||||||||

|

|  MIL-G-81737A(AS)

TABLE II.

Quality conformance inspection

REQUIREMENT

METHOD

SEQUENCE

EXAMINATION OR TEST

PARAGRAPHS

PARAGRAPH

1

Workmanship/Examination of

3.7

4.6.1

product

Wiring and rotation

2

3.5.1

4.6.2

Leakage

3

3.5.5

4.6.5

4

3.5.7

4.6.7

Temperature switch

3.5.6

Pressure switch

5

4.6.6

3.5.2

6

Gel mobility (standard conditions)

4.6.3

7

3.7

4.6,1

Examination of product

4.7

Section 5

8

Packaging

CAUTION

The materials used in some of these

tests are volatile or caustic. Extreme

caution should be observed during the

following tests (see NAVAIR 19-1-112).

4.6 Methods of examination and test.

4.6.1 Examination of product. The units shall be examined for conformance

with this specification and applicable drawings with respect to workmanship,

material, dimensions, and markings.

4.6.2 Wiring and rotation. For both the Mod 0 and the Mod 1, examination

of the wiring and rotation shall be made to determine that the internal wiring

corresponds to the requirements of the specified documents and for use at the

voltage designated in the procurement document as follows:

4.6.2.1 Mod 0. Examination shall determine that the internal wiring to

the latching coil, heater coils, and motor shall correspond to the

requirements of the documents specified in DL2581669 for use at the voltage

designated (see 6.2).

4.6.2.2 Mod 1. Examination shall determine that the internal wiring to

the latching coil, overload relays, and motor shall correspond to the

requirements of the documents specified in DL1558AS100 for use at the voltage

designated (see 6.2).

4.6.3 Gel mobility.

7

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |