|

|||

|

Page Title:

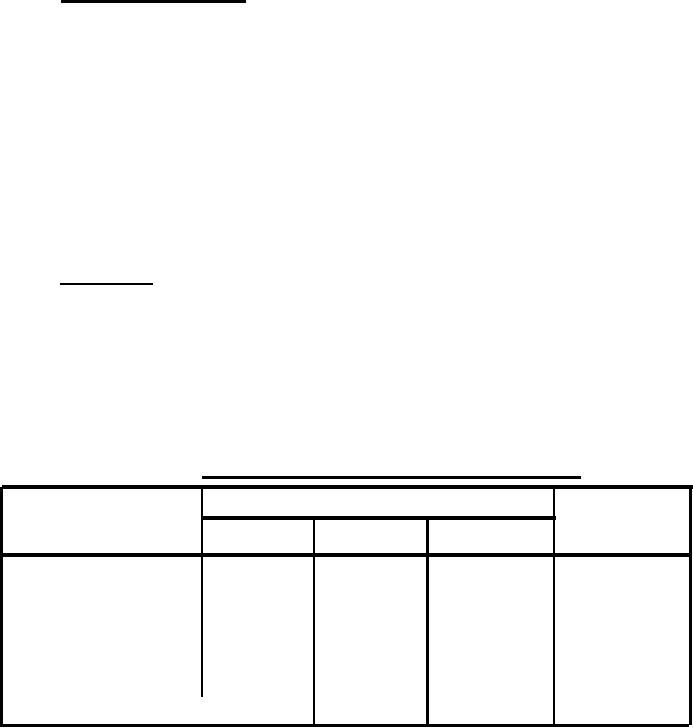

Table I. Load Application Points and Prestress Loads |

|

||

| ||||||||||

|

|  MIL-H-85042A(AS)

3.7 Prestressing of hooks. If required, to meet the dynamic loads (see 3.6),

each hook, after final processing, may be subjected to a prestress load level

(see 4.3.1 and 6.5) as determined and recommended by the contracting

activity. Determined prestress load values shall be considered valid only for

the particular heat of steel used in the manufacture of those hooks subjected

to prestress determination. Any subsequent heat shall require determination

of a new value. In the prestressung operation, the hook is to be held in a

test fixture as specified in 2.1. This results in the load on the hook being

concentrated on the lug bearing surface horizontally from the hook pivot hole

centerline as shown in Table I. The prestress load on the hook shall be

gradually increased for a period of 1 minute, held at the actual prestress

load for a minimum of 1 minutes and a maximum of one and one half minutes, and

gradually unloaded over a period of 1 minute. Following prestressing, the

hook shall be subjected to the magnetic particle inspection specified in

4.6.2. Type IX and X hooks shall be prestressed as shown in Table 1.

3.8 Workmanship. The workmanship displayed in fabrication and assembly of

the hooks shall be such as to assure, within design limitations, the ability

-

Of the hooks to meet their performance requirements under all applicable

environmental conditions specified herein. Unauthorized repair, welding,

heavy burns, or parts assembled by introduction of high stresses not

prescribed in the drawings, are typical signs of inferior workmanship and

shall be cause for rejection. The standards of workmanship exhibited in the

approved first article sample, subject to any qualification stated in the

government's notice of approval, shall be determinative of the requirements of

the contract relative to workmanship.

LOAD APPLICATION POINTS AND PRESTRESS LOADS.

TABLE I.

1

DISTANCE "X" IN INCHES

PRESTRESS

LOAD

HOOK

DYNAMIC

PRESTRESS

(POUNDS)

ULTIMATE

TYPE

0.584

0.584

0.584

Type II

0.800"

0.800

0.800

Type III

0.737

0.737

0.737

20,600

Type IX

0.737

0.737

16,500

0.737

Type X

0.437

0.437

0.437

Type XI

The values of Table I have no tolerances because they are direct functions of

the test fixtures and the "X" distances will be properly met if the

requirements of 4.5 are met.

1 See figure 1 for illustration of "X" distance

4

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |