|

|||

|

|

|||

| ||||||||||

|

|  MIL-K-48196(MU)

4.3.1.1 Production lot. A lot shall consist of parts

and assemblies produced by one manufacturer in one unchanged

process, in accordance with the same drawing, same drawing

revision, same specification and same specification revision.

Drawing, specification and process changes not affecting

safety, performance, storage, or interchangability, as de-

termined by the Government, shall not necessitate changing

the lot interfix number. The criteria and procedures for the

assignment of lot numbers shall be in accordance with MIL-

STD-1168.

4.3.1.2 Inspection lot. A lot or batch and its forma-

tion, size, and presentation is described in MIL-sTD-105,

Section 5. Accordingly, a lot shall mean an inspection lot

and a batch shall mean an inspection batch for the purpose

of this specification. The manner in which each inspection

lot or batch is to be presented and identified by the con-

tractor, shall be designated or approved by the Government

representative.

4.3.2 Product inspection examination. Critical

characteristics shall require 100 percent inspection of all

items in the inspection lot. A sample shall be selected at

random from each inspection lot in accordance with the ap-

plicable major or minor characteristic table (see Table I

and Table II), and inspected for all characterisitcs in the

applicable classification. Any characteristics in the sample

found to be defective shall reject the inspection lot. Se-

quence for the inspection of characteristics in each classi-

fication need not be followed as long as all characteristic

inspections are performed.

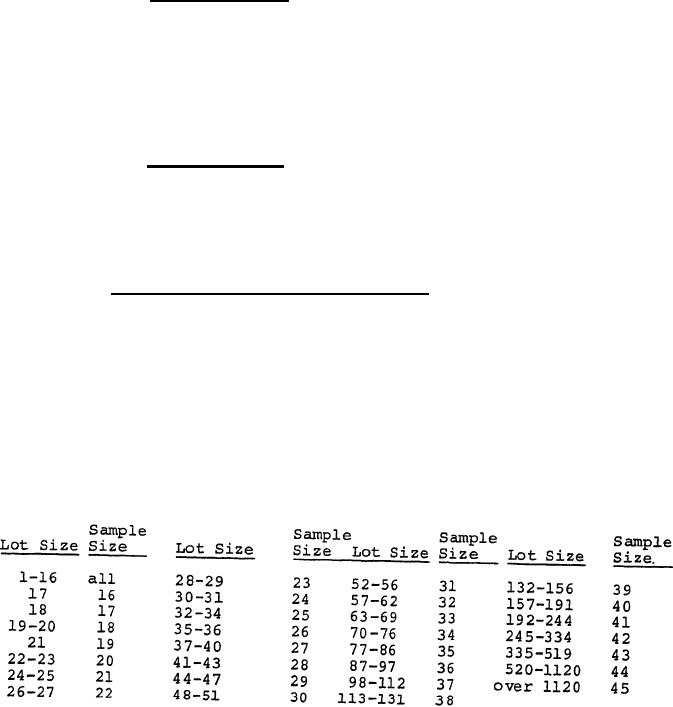

Table I

Major characteristics

3

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |