|

|||

|

|

|||

| ||||||||||

|

|  MIL-L-85776A(AS)

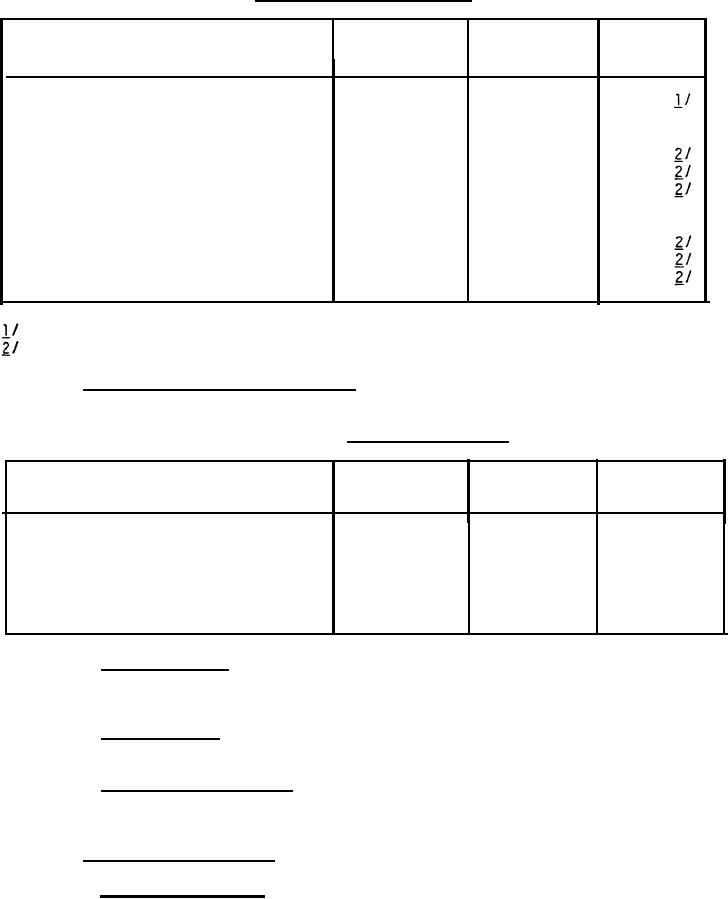

First article inspection.

TABLE I.

Number of

Method

Requirement

Inspection

samples

paragraph

paragraph

10

4.6.1

Visual

3.3

Environmental

High temperature

4.6.2

5

3.4

4.6.3

5

Low temperature

3.4

4.6.4

5

Humidity

3.4

Performance

3.5.1

4.6.5

5

Recycle time and amperage (M101)

4.6.6

5

Firing pin penetration (M102)

3.5.2

5

4.6.7

3.5.3

Discharge time and voltage (M103)

Samples consist of five launchers and five sets of unassembled metal parts.

Samples consist of five launchers.

4.5 Quality conformance inspection. Quality conformance inspection shall

consist of Group A inspection (see 6.6.1) specified in table II.

Group A inspection.

TABLE II.

Requirement

Method

Sampling

Inspection

procedures

paragraph

paragraph

4.5.2

Visual

4.6.1

3.2, 3.6

Performance

4.5.3

4.6.5

Recycle time and amperage (M1OI)

3.5.1

4.6.6

4.5.3

3.5.2

Firing pin penetration (M102)

4.5.3

Discharqe time and voltaqe (M103)

4.6.7

3.5.3

4.5.1 Inspection lot.

An inspection lot shall be as defined in MIL-STD-105

and shall consist of all launchers offered for inspection during a period of 1

month provided the homogeneity requirements of inspection lots have-been retained.

4.5.2 Sampling plan.

The sample size for visual inspection shall be in

accordance with MIL-STD-105, inspection level II.

4.5.3 Individual inspection.

Individual inspection is inspection conducted

Failure to pass inspection shall be

on each launcher (100 percent inspection).

cause for rejection of the launcher.

4.6

Methods of inspection.

Visual examination shall be made for such defects

4.6.1- Visual examination.

as defective metal, burrs, sharp corners, foreign matter, protective finish

defects, marking missing, incorrect or illegible, thread damaged or not full.

5

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |