|

|||

|

Page Title:

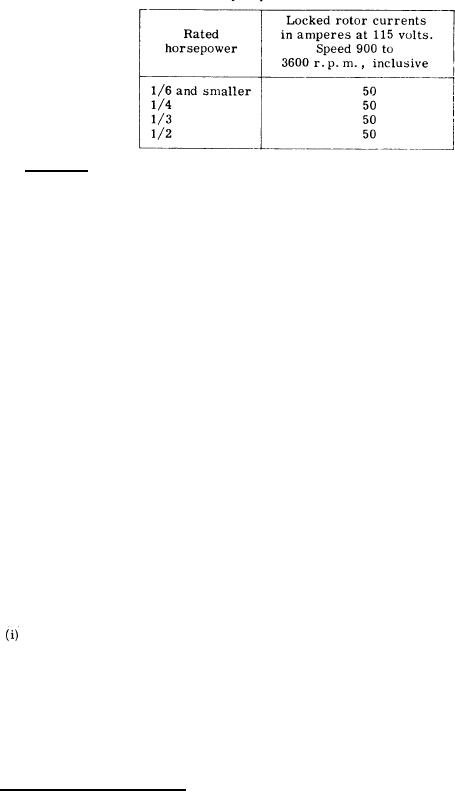

Table XI - Split-phase locked-rotor currents. |

|

||

| ||||||||||

|

|  MIL-M-17059A(SHIPS)

Table XI - Split-phase locked-rotor currents.

3.5.2.4 Drawings. - In addition to the requirements of 3.4 master drawings shall conform to figure 3 in

form and general arrangement and shall contain the following minimum data:

(a) An outline drawing giving all dimensions, clearance holes, tapped holes, holes for mounting and

position of mounting.

(b) Stator data including inside diameter, core length and winding data. Winding data to include:

Number of poles.

Type of connection.

Number of slots.

Number of coils.

Winding pitch in slots.

Turns in series per coil.

Conductor diameter.

Conductor insulation and Government specification.

Resistance between terminals in ohms.

Weight of copper in pounds.

(c) Treatment of wound stator. Number of dips and bakes including baking temperatures and period

of baking.

(d) Rotor data including outside diameter, number of bars, bar material, size of end ring, and

material of end ring.

(e) Insulation materials and applicable specification for the following:

Slot cell.

Spacer.

Top wedge.

U wedge (where used).

Insulation between phases.

Insulation on coil extension.

Insulation on coil leads and connections.

Insulation on completed windings.

Lead wire.

(f) Detail of slot section, showing details of slot wedges, slot armor, coil spacers and slot tubes.

(g) A detailed working drawing of the shaft.

(h) Schematic wiring diagram of motor windings and stator connection diagram.

Weight of complete motor in pounds.

(j) Guaranteed performance including locked-rotor current, locked-rotor torque, locked-rotor

power factor, pull-up torque, breakdown torque , and efficiency and power factor at 2/4, 3/4,

and 4/4 load.

(k) Title and classification block as required in 3.5.1.18(s) and (t)

(l) List of repair parts and tools with manufacturer's part numbers.

(m) A connection table of motor leads for two or more speed or dual voltage motors or both.

Terminal markings shall be shown on all connection and wiring diagrams.

4. QUALITY ASSURANCE PROVISIONS

4.1 Responsibility for inspection. - Unless otherwise specified in the contract or purchase order, the

supplier is responsible for the performance of all inspection requirements as specified herein. Except as

otherwise specified, the supplier may utilize his own facilities or any commercial laboratory acceptable to

the Government. The Government reserves the right to perform any of the inspections set forth in the

specification where such inspections are deemed necessary to assure supplies and services conform to

prescribed requirements.

22

I

A

I

I

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |