|

|||

|

Page Title:

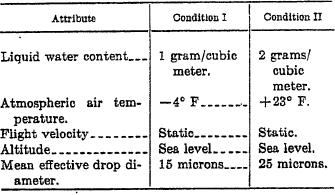

Table I. Ice control design conditions |

|

||

| ||||||||||

|

|  MIL-P-26366A

ous operation of the ice control system in flight

sient conditions of normal engine operation and

shall not damage the propeller system. Re-

within the Aq level specified in the model speci-

quirements for indication of the operation of

fication. Restrictions in propeller operating

the ice control system shall be specified in the

conditions determined by vibration surveys shall

model specification.

be listed in the model specification.

3.20.2 Electrical ice control system.

3 . 1 9 Propeller accessory limiting tem-

p e r a t u r e s . Engine and engine compartment

3.20.2.1 Electrical contact surface. All alu-

mounted propeller accessories shall be capable

minum-oxide films, lacquers, or similar noncon-

of continuous operation under normal operat-

ducting coatings shall be removed from the ac-

ing conditions and under the maximum temper-

tual contact area of all surfaces required to act

ature conditions anticipated in their environ-

as a path for electrical power and from the local

ment. Airframe mounted propeller accessories

areas under screws, nuts, or the like used for

other than the above shall be designed to meet

assembly or mounting purposes to provide an

the ambient temperature limitations of Specifi-

electrical connection in accordance with the re-

cation MIL-E-5272. Maximum temperatures

quirements of Specification MIL-W-5088.

of the environment and the accessories, heat re-

3.20.22 Electrical ice control circuits. All

jection rates, maximum endurance times and

electrical circuits pertaining to ice control sys-

maximum temperatures after shutdown, as ap-

tems shall be so physically and electrically iso-

p l i c a b l e , shall be specified in the model

lated that no interference with the propeller

specification.

operation or control will result. The leads used

3 . 2 0 Ice control system. The propeller

to conduct electrical power to the heating ele-

shall incorporate an ice control system for the

ments shall withstand the aerodynamic centrif-

blades, cuffs, and spinner. Either electrical,

ugal and vibratory loading to which they will

fluid, gas, compound, or mechanical ice control

be subjected during propeller operation.

systems or combinations of two or more of

3.20.2.3 Bonding materials. Cements, ad-

such systems may be used when approved

hesives, or brazing used to bond blade, spinner,

by the procuring activity. The ice control sys-

or cuff electrical heating elements shall be spec-

tem(s) shall be specified in the model specifica-

ified in the model specification. Bonding

tion. The propeller shall operate satisfactorily

processes which cause a reduction in physical

under the meteorological conditions included in

properties of the item to which the element is

table I.

b o n d e d shall be specified in the model

T ABLE I. Ice control design conditions

specification.

3.20.2.4 Cover surfaces. Surfaces exposed

to the air blast shall consist only of materials

designed to resist abrasion and corrosion. Ex-

ternal surfaces of installed heating elements

shall be aerodynamically smooth. Externally

mounted rubber or plastic surfaced elements

shall be inherently of sufficient flexibility and

elasticity to allow installation in service areas

without special dies, stretching equipment., etc.

3.20.2.5 Blade heating area. The heating

elements shall heat the inboard section of the

3.20.1 Type of ice control. The type of ice

exposed blade length to the propeller radius ap-

control may be continuous, cyclic, or a combina-

proved by the procuring activity. The width

tion of both as specified in the model specifica-

of the blade heated on both the thrust and cam-

tion. Unless continuous ice control is provided,

ber frees shall extend from the leading edge

operation of the ice control system shall be ac-

back to a distance at no point less than 17

complished either automatically or manually as

percent of the blade chord.

specked in the model specification. Continu-

7

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |