|

|||

|

Page Title:

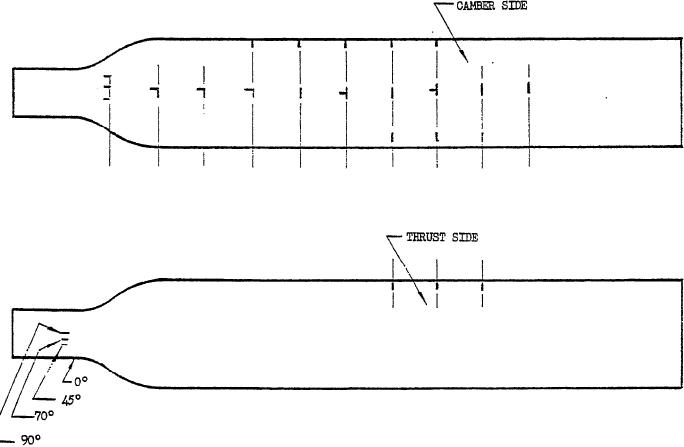

Figure 5. Typical strain gage layout. |

|

||

| ||||||||||

|

|  MIL-P-26366A

the number of strain gages and types of each

Ambient temperature, F.*

used, their distribution, the range of operat-

Established formula for determining cor-

ing conditions over which vibratory stress data

rected horsepower, thrust, and torque.

will be recorded, the type of recording equip-

Data for reading oscillograph recordings

ment used and the intervals at which record-

of stress traces.

ings will be made, and the propeller com-

*Note. Ambient temperature shall be recorded

ponents to be subjected to the vibratory

at intervals not greater than 60 minutes.

stress survey shall be subject to review and

4.5.1.2 Teardown inspection. The propeller

approval by the procuring activity. Addi-

submitted for test shall be completely disas-

tional or revised instrumentation similar in

sembled to allow a detailed inspection of all

nature is permitted. The instrumentation shall

vital working parts. Those components which

be sufficient to record stress traces, propeller

are permanently joined together will be ex-

rpm, and blade angle. The following is pro-

cepted. Individual parts or components shall

vided as a guide for the survey. Strain gages

be examined for evidence of suitable quality of

shall be installed on one blade of the propeller

materials based on physical inspections and

substantially in accordance with figure 5 for

process control data and may be supplemented

measurement of blade shank longitudinal bend-

by physical and chemical tests to determine the

ing and transverse stresses. A limited number

extent of conformance to contractor's specifica-

of strain gages shall be installed on adjacent or

tions and drawings. The condition of the in-

opposite or both adjacent and opposite propeller

dividual parts or components shall be recorded.

blades, as required. Instrumentation data for-

Periodic inspection during tests will be ap-

mat for strain, gage installation on the propeller

proved by the procuring activity.

blade and their respective connection to the re-

4.5.1.3 Instrumentation. The instrumenta-

cording oscillograph used f or making the vibra-

tion and techniques used for recording the

tory stress data shall be prepared substantially

in accordance with figures 6 and 7.

vibratory stress survey of the whirl stand tests.

F IGURE 5. Typical strain gage layout.

20

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |