|

|||

|

|

|||

| ||||||||||

|

|  MIL-P-26366A

( f ) Detection of excessive wear of any

part or component during teardown

inspection.

(g) Necessity to add operating fluid, if ap-

plicable.

In the event. of a discrepancy of a propeller com-

ponent, a. suitable retest penalty maybe imposed

at the discretion of the procuring activity.

4.5.3 Preliminary aircraft test.

4.5.3.1 Test conditions.

4.5.3.1.1 Test apparatus. The following test

apparatuses shall apply for all preliminary air-

craft tests, as applicable.

4.5.3.1.1.1 Aircraft test bed. The prelimin-

ary aircraft test of the propeller shall be con-

ducted on an aircraft test bed or a suitable air-

craft having a nacelle configuration similar to

the proposed application.

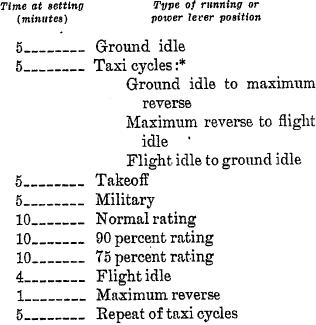

*Note: Repeat approximately 10 times with alter-

4.5.3.1.2 Test propeller. The same test pro-

nate slow and rapid power lever motion.

peller shall be used for all the preliminary air-

The engine test observed data shall be prepared

craft tests and shall be in accordance with the

substantially in accordance with figure 15.

contractor's model specification.

4.5.2.9 Teardown inspection. After comple-

4.5.3.1.3 Test data. During the preliminary

tion of the 50-hour engine test, the propeller

aircraft test, all pertinent test data provisions of

a n d components shall be completely dis-

4.5.2.1.3 shall be applicable. In addition, re-

assembled for examination in accordance with

cordings shall be made of the pertinent aircraft

the provisions of 4.5.1.9.

performance parameters.

4.5.2.10 Deviation from normal operation.

4.5.3.2 Instrumentation. The instrumenta-

Whenever there is evidence that the propeller is

tion and techniques used for monitoring the

deviating from normal operation or is not

required vibratory stress survey of the prelimi-

meeting the contractor's model specification re-

nary aircraft test shall be as specified in 4.5.1.3.

quirements during the testing specified in 4.5.2.8,

In addition, the following instrumentation is

the discrepancy shall be immediately reported

provided as a guide. The instrumentation shall

to the Government representative, If any of

be sufficient to provide a continuous record of

the following discrepancies are detected after

power lever position, pitch angle in degrees, yaw

starting of the cyclic test, the number of credita-

angle in degrees, and a coordinating signal from

ble hours of testing shall be disallowed:

the photo panel frame counter. Visual indicat-

(a) Linkages pertaining to the propeller

ing instruments shall be provided to the pilot for

require adjustment.

yaw angle in degrees. The wiring to the nacelle

(b) Propeller speed setting exceeds the es-

and cabin shall consist of a pair of shielded wires

tablished schedule by 0.5 percent.

(No. 22 AWG or larger) with adequate insulat-

(c) Failure of any component adversely

ing jacket over each shield. All wires and

affecting propeller control perform-

shields shall be insulated from the aircraft's

ance.

ground and from each other. The power bat-

(d) Failure of any component adversely

teries for the recording equipment. shall be of

affecting propeller integrity.

sufficient capacity to stand the current draw of

(e) Detection of any failure of any com-

the maximum circuitry without jeopardy to

ponent directly or indirectly affecting

data recording. When utilized, the strain gage

control performance during teardown

batteries shall be of sufficient capacity to with-

inspection.

stand the maximum steady drain without jeop-

34

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |